English

English

1. OVERVIEW

1. OVERVIEW

G85139-H1751-U529-D1

G85139-H1751-U529-D1

© Siemens plc 1999

© Siemens plc 1999

4/8/99

4/8/99

6

6

1. OVERVIEW

1. OVERVIEW

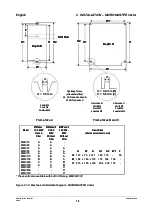

The MICROMASTER Vector (MMV) and MIDIMASTER Vector (MDV) are a standard range of inverters with

The MICROMASTER Vector (MMV) and MIDIMASTER Vector (MDV) are a standard range of inverters with

sensorless vector

sensorless vector capability suitable

capability suitable for controlling the

for controlling the speed of 3

speed of 3 phase motors.

phase motors. Various models

Various models are

are

available, ranging from the compact 120 W MICROMASTER Vector up to the 75 kW MIDIMASTER Vector.

available, ranging from the compact 120 W MICROMASTER Vector up to the 75 kW MIDIMASTER Vector.

Sensorless vector control allows the inverter to calculate the changes required in output current and frequency

Sensorless vector control allows the inverter to calculate the changes required in output current and frequency

in order to maintain the desired motor speed across a wide range of load conditions.

in order to maintain the desired motor speed across a wide range of load conditions.

For additional product information such as application examples, part numbers, operation with long cables etc,

For additional product information such as application examples, part numbers, operation with long cables etc,

please refer to catalog DA64 or to

please refer to catalog DA64 or to

http://www.con.siemens.co.uk

http://www.con.siemens.co.uk

Features:

Features:

••

Easy

Easy to

to install,

install, program

program and

and commission.

commission.

••

Overload

Overload capability

capability 200%

200% for

for 3s

3s followed

followed by

by 150%

150% for

for 60s.

60s.

••

High

High starting

starting torque

torque and

and accurate

accurate motor

motor speed

speed regulation

regulation by

by vector

vector control.

control.

••

Optional i

Optional integrated RFI

ntegrated RFI filter on

filter on single-phase

single-phase input inv

input inverters MMV12

erters MMV12 - MMV

- MMV 300, and

300, and three phase

three phase input

input

inverters MMV220/3 to MMD750/3

inverters MMV220/3 to MMD750/3

••

Fast

Fast Current

Current Limit

Limit (FCL)

(FCL) for

for reliable

reliable trip-free

trip-free operation.

operation.

••

0

0 to

to 50

50

°°

C temperature range (0 to 40

C temperature range (0 to 40

°°

C for MIDIMASTER Vector)

C for MIDIMASTER Vector)

••

Closed lo

Closed loop process

op process control using

control using a standard

a standard Proportional, Integ

Proportional, Integral, Derivativ

ral, Derivative (PID)

e (PID) control loop

control loop function.

function.

15 V, 50 mA supply provided for feedback transducer.

15 V, 50 mA supply provided for feedback transducer.

••

Remote control

Remote control capability

capability via RS485

via RS485 serial li

serial link using

nk using the USS

the USS protocol w

protocol with the

ith the ability to

ability to control up

control up to 31

to 31

inverters via the USS protocol.

inverters via the USS protocol.

••

Factory

Factory default

default parameter

parameter settings

settings pre-programmed

pre-programmed for

for European,

European, Asian

Asian and

and North

North American

American

requirements.

requirements.

••

Output

Output frequency

frequency (and

(and hence

hence motor

motor speed)

speed) can

can be

be controlled

controlled by:

by:

(1)

(1) Frequency setp

Frequency setpoint using

oint using the keypad.

the keypad.

(2)

(2) High resolution analogu

High resolution analogue setpoint (voltage or

e setpoint (voltage or current input).

current input).

(3)

(3) External potentiometer

External potentiometer to control

to control motor speed.

motor speed.

(4)

(4) 8 fixed

8 fixed frequencies via

frequencies via binary inputs.

binary inputs.

(5)

(5) Motorised

Motorised potentiometer

potentiometer function.

function.

(6)

(6) Serial

Serial interface.

interface.

••

Built-in

Built-in DC

DC injection

injection brake

brake with

with special

special COMPOUND

COMPOUND BRAKING.

BRAKING.

••

Built-in

Built-in brake

brake chopper

chopper for

for external

external resistor

resistor (MMV).

(MMV).

••

Acceleration/deceleration

Acceleration/deceleration times

times with

with programmable

programmable smoothing.

smoothing.

••

Two

Two fully-programmable

fully-programmable relay

relay outputs

outputs (13

(13 functions).

functions).

••

Fully-programmable

Fully-programmable analogue

analogue outputs

outputs (1

(1 for

for MMV,

MMV, 2

2 for

for MDV).

MDV).

••

External Opti

External Options connec

ons connector for

tor for optional

optional multi-language

multi-language Clear

Clear Text D

Text Display

isplay (OPM2), optional

(OPM2), optional PROFIBUS-

PROFIBUS-

DP module or CANbus module

DP module or CANbus module

••

Dual

Dual motor-parameter

motor-parameter sets

sets available

available if

if Clear

Clear Text

Text Display

Display (OPM2)

(OPM2) fitted.

fitted.

••

Automatic

Automatic recognition

recognition of

of 2,4,6

2,4,6 or

or 8-pole

8-pole motors

motors by

by software.

software.

••

Integral

Integral software

software controlled

controlled cooling

cooling fan.

fan.

••

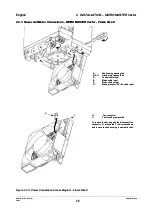

Side-by-side

Side-by-side mounting

mounting without

without additional

additional clearance.

clearance.

••

Optional

Optional protection

protection to

to IP56

IP56 (NEMA

(NEMA 4/12)

4/12) for

for MIDIMASTER

MIDIMASTER Vector

Vector inverters.

inverters.