- 24 -

Caution: Injury to Eyes and Skin

Always be sure to wear arc-proof glasses (refer to the table below), clothes that

completely cover the skin and other protective gear when welding to protect the

eyes and skin from harmful light rays generated during welding.

Standards for Arc-Proof Glasses (Japanese Industrial Standard)

Filter No.

7

8

9

10

11

12

13

14

Weld

Current

(A)

Shielded metal arc welding

35-75

76-200

201-400

400-

Gas-shielded arc welding

---

--- 100 or less

101-300

301-500

Gouging

---

---

---

126-225

226-350

---

Caution: Electric Shock

If wearing gloves, be sure to always wear gloves with dry insulation properties. Do

not wear gloves that are damaged or wet.

You can select from among five weld modes in accordance with the type of welding

being performed. Select a weld mode by referring to the recommended modes in the

table below.

Weld Modes Table (Recommended)

Mode Name

Applications

Welding

Position

CV

WIRE

Semi-automatic Arc Welding

(MIG, MAG, self-shielded, and

similar welding)

All directions

DROOP

CELLULOSE ROD

Welding of pipes, tanks and

similar items

Vertical

and

Upward

STANDARD ROD

GOUGING

Welding of pipes, tanks and

similar items

Gouging

CC

CELLULOSE ROD

SCRATCH START TIG

Welding of structures and

finishing welding

TIG welding

Horizontal

and

Downward

STANDARD ROD

Welding of heavy structures

and thick plates

<Note>

This equipment allows for 2-person simultaneous welding. For 2-person simultaneous

welding, select a weld mode and adjust the weld output in accordance with each type

of welding work being performed.

The range of weld output that can be adjusted using the output control dial varies

depending on the positions of the single/dual selector, weld mode selector and

frequency selector. (Refer to section "2. Specifications".)

(1) Semi-automatic Arc Welding

1)

Set the weld mode selector to "CV-WIRE".

2)

Switch the single/dual selector in accordance with the amount of welding personnel

and desired weld output.

3)

Set the output control dial to the desired voltage.

4)

Start the engine. (Refer to section "8-1. Starting the Engine".)

5)

Set the wire feed speed of the wire feeder.

6)

While an arc is being generated, adjust the output control dial of the equipment or

remote controller so that the arc is stabilized.

Single/Dual Selector

Output Control Dial

Arc Control Dial

Weld Mode Selector

Wire

Feeder

Equipment

Work

Weld Power Cable

Output Control Dial

Work Clip Lead

Содержание DGW400DMK

Страница 2: ......

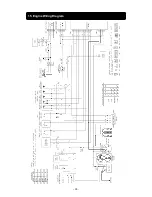

Страница 41: ... 38 15 Engine Wiring Diagram ...

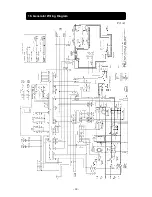

Страница 42: ... 39 16 Generator Wiring Diagram P 1 2 ...

Страница 43: ... 40 P 2 2 ...

Страница 44: ... 41 MEMO ...

Страница 45: ... 42 MEMO ...

Страница 46: ... 43 MEMO ...

Страница 47: ... 44 ...

Страница 48: ... 45 2015 ...