- 36 -

Refer to the table below to perform inspection when the equipment is operating poorly.

If you cannot resolve a problem after inspecting the equipment, request repair at the

retail outlet where the equipment was purchased.

Symptom

Possible Causes

Remedy

Starter motor does

not start.

1. Battery has a low charge.

2. Battery is deteriorated.

1. Recharge the battery.

2. Replace the battery.

Engine does not

start.

1. Fuel lever is "CLOSE".

2. Emergency stop switch is "ON".

3. No fuel.

4. Water or foreign material is mixed

in with the fuel.

5. Blown fuse.

1. Turn the fuel lever to "OPEN".

2. Release the emergency stop switch.

3. Add fuel.

4. Drain water from and clean the fuel

tank and fuel strainer.

5. Replace the fuse.

Engine starts but

quickly stops.

1. Insufficient oil.

2. Overheating of water temperature.

3. Battery recharging fault.

1. Add oil.

2. Comply with rated outputs/Add cooling

water.

3. Repair.

Black or white smoke

is continuously

exhausted from the

muffler.

1. Overloaded.

1. Comply with the rated outputs.

Engine does not

stop.

1. Stop solenoid fault.

1. Turn the fuel lever to "CLOSE" to stop

the engine.

Weak welding arc

1. Single/Dual selector is set to

"DUAL".

2. Faulty cable connection.

3. Improper cable. (excessively thin)

4. Faulty connection with base

material.

5. Using simultaneously as AC

power source.

6. Welding cable short circuit.

7. Frequency selector is wrong

setting.

1. Set to "SINGLE".

2. Connect securely.

3. Replace with cable according to

"Welding Cable Selection".

4. Connect securely.

5. Do not use as AC power source.

6. Remove the cause of the short circuit.

7. Set to proper frequency.

Strong welding arc

1. Single/Dual selector is set to

"SINGLE".

2. Arc control setting is excessively

strong.

1. Set to "DUAL".

2. Turn the arc control dial to the left.

Wire feeder cannot

be used.

1. "DROOP" or "CC" weld mode has

been selected.

2. Poor connection of the wire feeder

connector.

1. Set to "CV-WIRE".

2. Securely connect the wire feeder

connector.

Weld output cannot

be adjusted.

1. Remote controller is connected.

1. Disconnect the remote controller.

Or, adjust using the remote controller.

No AC power output

1. Breaker is "OFF".

1. Turn the breaker to "ON".

AC power output is

weak.

1. Frequency selector is wrong

setting.

2. The current of devices using the

equipment exceed the rated

current.

3. Using simultaneously for welding.

1. Set to proper frequency.

2. Refer to "Usable Device Capacities".

3. Stop welding.

Engine cannot obtain

high speed.

1. Idle control switch is set to "ECO".

2. Current of device using the

equipment as AC power source is

0.5A or less.

1. Set to "HIGH" or "AUTO".

2. Set the idle control switch to "HIGH".

Engine cannot obtain

low speed.

1. Idle control switch is set to

"HIGH".

2. Welding cable short circuit

1. Set to "ECO" or "AUTO".

2. Remove the cause of the short circuit.

Содержание DGW400DMK

Страница 2: ......

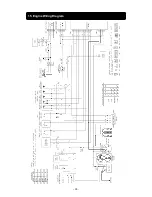

Страница 41: ... 38 15 Engine Wiring Diagram ...

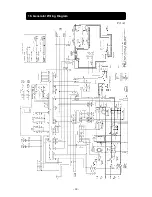

Страница 42: ... 39 16 Generator Wiring Diagram P 1 2 ...

Страница 43: ... 40 P 2 2 ...

Страница 44: ... 41 MEMO ...

Страница 45: ... 42 MEMO ...

Страница 46: ... 43 MEMO ...

Страница 47: ... 44 ...

Страница 48: ... 45 2015 ...