- 20 -

0-0 Basic screen

2-0

ENT

DISP

DISP

2-1

to the 2--2 screen

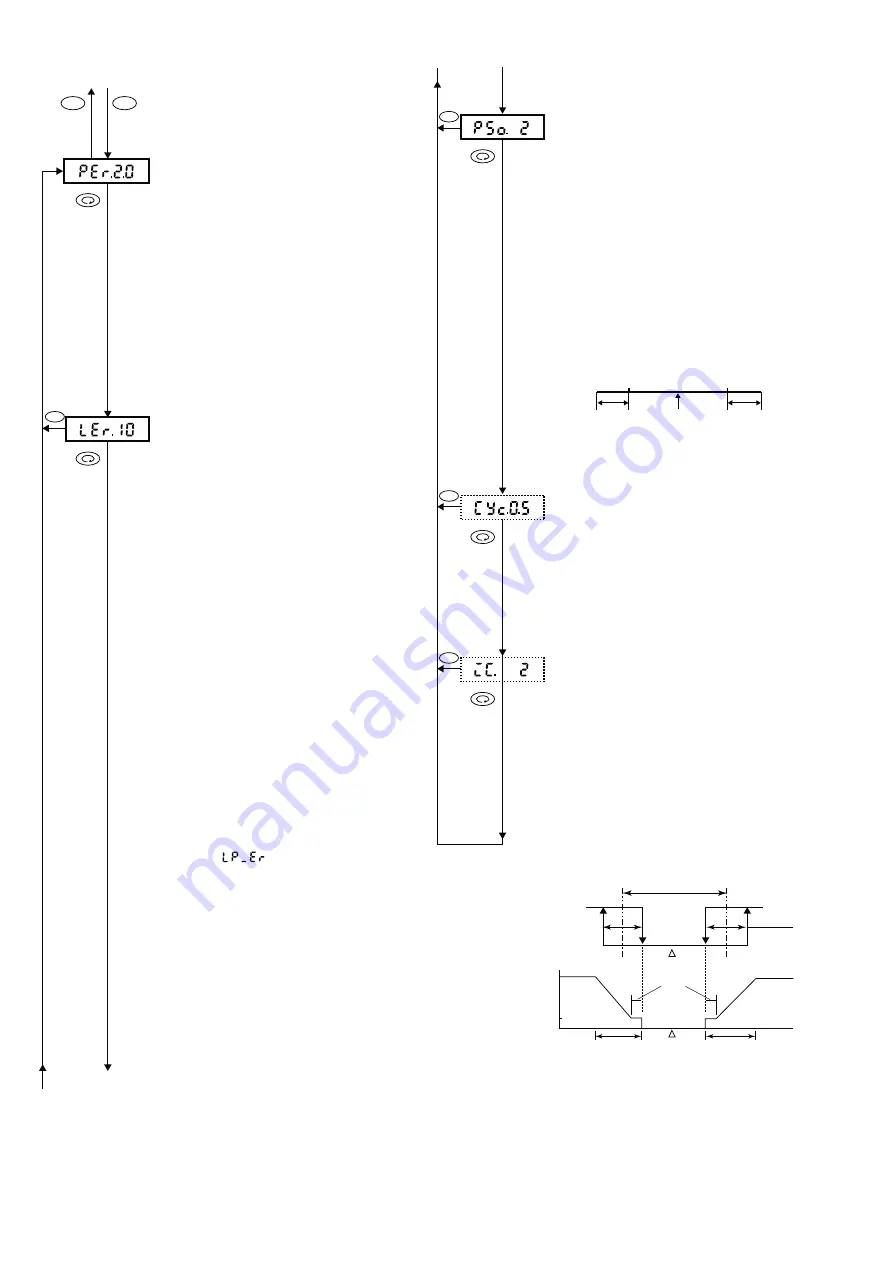

(1) Setting Delay Time upon Occurrence of

Position Error

Screen for setting delay time upon

occurrence of position error

Initial value: 2.0 seconds

Setting range: 0.0~9.9 seconds

A delay time from the detection of

position error to the position error is set.

If a position error occurs while the 0-0

basic screen is on display, the 0-0-2

position display screen returns and the

2 digits on the right blink to signify a

position error.

If a position error occurs while any

screen other than the 0-0 basic screen is

on display, the POSITION lamp blinks.

(2) Setting Detection Time for Control Loop

Error

Control loop error detection time setting

screen

Initial value: 10 seconds

Setting range: 5~60 seconds

A control loop error means that a

feedback potentiometer input signal does

not correspond to control output. The

response of the feedback potentiometer

to control output changes in accordance

with the speed of a control motor to be

used. In case the speed of motor is high

(the time between full close and full open

is short) and it is intended to quicken the

control loop error detection, a shorter

detection time is set. In this case, lower

motor speed tends to result in erroneous

detection. An excessively low motor

speed (the time between full close and

full open is longer than 250 seconds)

makes a change per unit time of the

feedback potentiometer very small,

leading to the possibility that a normal

condition is taken as a control loop error.

If this is the case, set a longer time for

control loop error detection.

Use 4% or more of the time between full

close and full open as a guideline for

your setting.

When a control loop error occurs on the

DES/DEV display screen, the error

message appears. At the same

time, the 2 digits from the right blink and

the DES/DEV lamp lights.

In case a control loop error and a position

error occur simultaneously, the position

error is given preference and the control

loop error check is released.

Refer to the following formula in setting

the control loop error detection time.

Set value of control loop error detection

time > 4 x T/G

T : Motor action time (second)

G: Motor speed adjustment setting (%)

Even when a position error is not

detected in the case of R1 or R3 break,it

may be detected as a control loop error.

5 seconds

2-2

2-3

(3) Setting of Position Error Range

Position error range setting screen

Initial value: 2%

Setting range: 1 ~10%

What percentage by which a position

value is deviated from the 1 to 100%

range is to be judged as a position error

(position scaleover) is set.

In case the position error range is set at

3%, a value lower than

-

3% or more than

103% is judged as a position error.

In setting a position error range, a value

to be set should be within a residual

resistance range from the limiter switch

to the potentiometer. A value set outside

the residual resistance range is not taken

as a position error but a control loop

error is output.

(4)

Setting of Cycle Time of Motor Speed

Adjustment

Motor speed adjustment cycle time

setting screen

Initial value: 0.5 seconds

Setting range: 0.5~9.9 seconds

In the case of SSR output, a cycle time of

motor speed adjustment is set. For setting

motor speed adjustment, see 1-32 Motor

adjustment setting screen.

(5)

Setting of Inching Action Range

Inching action range setting screen

Initial value: OF

Setting range: OF, 1~10%

(OF: No inching action)

When the absolute value of deviation enters

the inching action range, the deviation value

and the proportional inching action will

automatically take place.

(However, setting is possible only in case of

SSR output)

Potentiometer

Limit switch

0%

R1

R2

R3

100%

Limit switch

Residual

resistance

Residual

resistance

DISP

2-4

DISP

DISP

Example: Relations of inching action, dead

band and hysteresis.

(When motor speed G=100%)

continued to the right top

Output

ON

Output

OFF

Dead band DB

Target value

of position

Hysteresis

0.5%

100%

10%

Motor speed G

Inching action

setting range

Inching action

setting range