Page 35

When using the tool station, crank the bar shear hold-down device completely down and remove the

punch and die. As with all functions on this machine, SAFETY GLASSES ARE REQUIRED when using

optional tools of any type. Each self contained tool has its own stroke and tonnage requirements. This

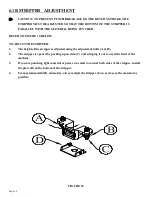

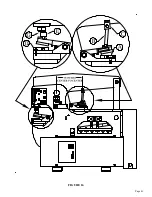

section will cover the operation and location of each tool. There is a graphical illustration of the available

tonnage at locations along the Upper Arm. SEE FIGURE 13 BELOW. This graph will be helpful in

setting up various Scotchman or custom tooling.

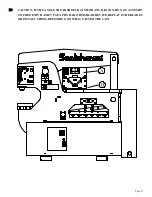

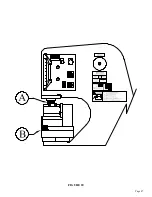

7.0 OPTIONAL TOOL OPERATION

The 6 x 6 angle shear is a component tool designed to shear angle iron. It installs in the tool station on

this machine and has a maximum capacity of 6 x 6 x 1/2 inch (152 x 152 x 12mm) mild steel angle iron.

The selector switch must be in the SHEAR position to operate this tool.

7.1 6 X 6 ANGLE SHEAR

CAUTION: MOVE ALL TOOLS OUT FROM UNDER THE UPPER ARM WHEN THEY ARE

NOT IN USE.

FIGURE 13

WARNING

SAFETY GLASSES REQUIRED WHEN

OPERATING OR OBSERVING THIS MACHINE

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

NEVER-

TO PREVENT SERIOUS BODILY INJURY

Operate, install tooling, service or adjust machine without

operator's manual and safety film.

Service machine with electrical power connected.

Operate any station without the respective strippers or

Operate machine with protective guards removed.

Place any part of your body under blade, punch or moving

Operate punch station without checking the punch to die

alignment and tightness.

Punch half holes, punch or shear unknown materials, side load

DO NOT REMOVE THIS SIGN FROM THIS MACHINE

REV. 0310

FOR MORE INFORMATION CONTACT SCOTCHMAN INDUSTRIES INC.

1-800-843-8844

003100

proper instructions and without reading and understanding the

hold-downs in place.

members.

(Check alignment and tightness daily.)

press brakes.

AT

SERIAL

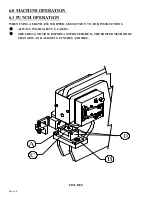

SCOTCHMAN INDUSTRIES, INC.

PHILIP, SOUTH DAKOTA, U.S.A.

MADE IN U.S.A.

MODEL

FLA

HZ

PH

H.P.

VOLT

BLADE LENGTH

PH. 605-859-2542

PSI

LUBRICATE

BEFORE

OPERATING

19103

0481

9012-24M

MACHINE CAPACITIES

SPEC. BASED ON MILD STEEL-65,000 PSI TENSILE

PUNCH

PUNCH

THROAT DEPTH

STROKE

FLAT SHEAR

ANGLE SHEAR

90 TONS

Ø27 THRU 25MM

Ø1-1/16 THRU 1"

2.25" - 57MM

12" - 300MM

150X150X12MM

6"X6"X 1/2"

25X200 - 6X600MM

1X8 - 1/4X 24"

BLADE LENGTH 24" - 600MM

#019139

5,03

JOG

START

STOP

RUN

JOG

START

SHEAR

PUNCH

PROBE

004085

1711 Sales - 1710 Assy.

10

20

30

40

50

60

70

4

8

12

16

20

24

FORCE IN

U.S. TONS

2.5

3.25

4.0

4.5

5.25

6.0

STROKE IN INCHES

80

90

DISTANCE FROM

FRAME IN INCHES

Содержание 9012-24M

Страница 10: ...Page 9 FIGURE 1 ...

Страница 12: ...Page 11 FIGURE 2 ...

Страница 16: ...Page 15 FIGURE 4A ...

Страница 17: ...Page 16 FIGURE 4B ...

Страница 18: ...Page 17 FIGURE 4C ...

Страница 22: ...Page 21 FIGURE 6 ...

Страница 24: ...Page 23 FIGURE 7 ...

Страница 35: ...Page 34 THIS PAGE LEFT BLANK INTENTIONALLY ...

Страница 40: ...Page 39 FIGURE 15 ...

Страница 42: ...Page 41 FIGURE 16 ...

Страница 48: ...Page 47 FIGURE 20 ...

Страница 54: ...Page 53 FIGURE 24 ...

Страница 56: ...Page 55 FIGURE 25 ...

Страница 62: ...Page 61 FIGURE 27 ...

Страница 66: ...Page 65 FIGURE 29 ...

Страница 68: ...Page 67 FIGURE 30 ...

Страница 74: ...Page 73 FIGURE 32 ...

Страница 78: ...Page 77 FIGURE 34 ...

Страница 80: ...Page 79 FIGURE 35 ...

Страница 82: ...Page 81 FIGURE 36 ...

Страница 84: ...Page 83 FIGURE 37 ...

Страница 86: ...Page 85 FIGURE 38 ...

Страница 90: ...Page 89 FIGURE 41 ...

Страница 92: ...Page 91 FIGURE 42 ...

Страница 93: ...Page 92 FIGURE 43 ...

Страница 96: ...Page 95 THIS PAGE LEFT BLANK INTENTIONALLY ...

Страница 98: ...Page 97 FIGURE 46 ...

Страница 100: ...Page 99 FIGURE 47 ...