Содержание NSR-A 100

Страница 1: ...Translation of Original Operating Manual Assembly and Operating Manual NSR A Pallet Changing System ...

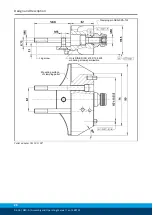

Страница 62: ...Maintenance 62 06 00 NSR A Assembly and Operating Manual en 389722 7 4 2 Assembly drawings NSR A 160 ...

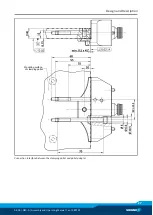

Страница 63: ...Maintenance 06 00 NSR A Assembly and Operating Manual en 389722 63 Without adapter plate ...