Basic safety notes

06.00 | NSR-A | Assembly and Operating Manual | en | 389722

15

2.13.2 Protection during commissioning and operation

Falling or violently ejected components

Falling and violently ejected components can cause serious injuries

and even death.

• Take appropriate protective measures to secure the danger

zone.

• Never step into the danger zone during operation.

2.13.3 Protection against dangerous movements

Unexpected movements

Residual energy in the system may cause serious injuries while

working with the product.

• Switch off the energy supply, ensure that no residual energy

remains and secure against inadvertent reactivation.

• Never rely solely on the response of the monitoring function to

avert danger. Until the installed monitors become effective, it

must be assumed that the drive movement is faulty, with its

action being dependent on the control unit and the current

operating condition of the drive. Perform maintenance work,

modifications, and attachments outside the danger zone

defined by the movement range.

• To avoid accidents and/or material damage, human access to

the movement range of the machine must be restricted. Limit/

prevent accidental access for people in this area due through

technical safety measures. The protective cover and protective

fence must be rigid enough to withstand the maximum possible

movement energy. EMERGENCY STOP switches must be easily

and quickly accessible. Before starting up the machine or

automated system, check that the EMERGENCY STOP system is

working. Prevent operation of the machine if this protective

equipment does not function correctly.

2.13.4 Protection against electric shock

Possible electrostatic energy

Components or assembly groups may become electrostatically

charged. When the electrostatic charge is touched, the discharge

may trigger a shock reaction leading to injuries.

• The operator must ensure that all components and assembly

groups are included in the local potential equalisation in

accordance with the applicable regulations.

• While paying attention to the actual conditions of the working

environment, the potential equalisation must be implemented

by a specialist electrician according to the applicable

regulations.

• The effectiveness of the potential equalisation must be verified

by executing regular safety measurements.

Содержание NSR-A 100

Страница 1: ...Translation of Original Operating Manual Assembly and Operating Manual NSR A Pallet Changing System ...

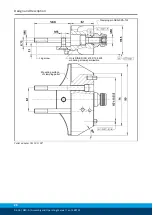

Страница 62: ...Maintenance 62 06 00 NSR A Assembly and Operating Manual en 389722 7 4 2 Assembly drawings NSR A 160 ...

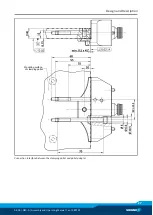

Страница 63: ...Maintenance 06 00 NSR A Assembly and Operating Manual en 389722 63 Without adapter plate ...