26

EB 8091-1 EN

Mounting and start-up

3. Lift the valve to the site of installation.

Observe the flow direction through the

valve. The arrow on the valve indicates

the direction of flow.

4. Make sure that the correct gaskets are

used on the end connections.

5. Bolt the pipe to the valve free of stress.

6. Depending on the field of application,

allow the valve to cool down or heat up

to reach ambient temperature before

start up.

7. Slowly open the shut-off valve in the

pipeline after the valve has been in-

stalled.

Risk of valve damage due to a sudden pres-

sure increase and resulting high flow veloci

-

ties.

Slowly open the shut-off valve in the pipeline

during start-up.

8.

Check the valve to ensure it functions

properly.

Version with welding ends

1. Proceed as described for Version with

female thread or flanges (steps 1 to 3).

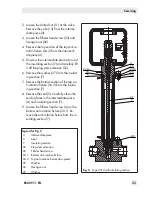

2. Completely retract the actuator stem to

protect the plug from sparks during weld-

ing.

3. Weld the valve free of stress into the

pipeline.

4. Proceed as described for Version with fe-

male thread or flanges (steps 6 to 8).

5.3 Quick check

SAMSON valves are delivered ready for

use. To test the valve's ability to function, the

following quick checks can be performed:

Tight shut-off

1. Close the valve.

2. Slowly open the shut-off valve in the

pipeline.

Risk of valve damage due to a sudden pres-

sure increase and resulting high flow veloci

-

ties.

Slowly open the shut-off valve in the pipeline

during start-up.

3. Check the valve for leakage (visual in-

spection).

Travel motion

The movement of the actuator stem must be

linear and smooth.

Î

Open and close the valve, observing the

movement of the actuator stem.

Î

Apply the maximum and minimum con-

trol signals to check the end positions of

the valve.

Î

Check the travel reading at the travel in-

dicator scale.

Fail-safe position

Î

Shut off the signal pressure line.

Î

Check whether the valve moves to the

fail-safe position.

NOTICE

!

NOTICE

!

Содержание 3510

Страница 29: ...EB 8091 1 EN 29...