EB 8091-1 EN

25

Mounting and start-up

The workplace of operating personnel is the

location from which the valve, actuator and

any mounted valve accessories can be ac-

cessed to operate them.

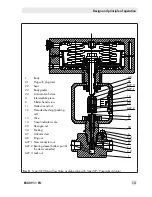

5.2.2

Additional fittings

Strainers

We recommend installing a SAMSON

strainer upstream of the valve. It prevents sol-

id particles in the process medium from

damaging the valve.

Bypass and shut-off valves

We recommend installing a shut-off valve

both upstream of the strainer and down-

stream of the valve and setting up a bypass

line. The bypass ensures that the plant does

not need to be shut down for service and re-

pair work on the valve.

Insulation

Only insulate control valves with insulating

section or bellows seal up to the bonnet

flange of the valve body for medium tem-

peratures below 32 °F (0 °C) and above

428 °F (220 °C).

Do not insulate valves mounted to comply

with NACE MR 0175 requirements.

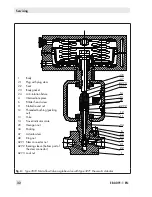

Test connection

Versions with bellows seal fitted with a test

connection (G

1

/

8

) at the top flange allow the

sealing ability of the bellows to be moni-

tored.

Particularly for liquids and vapors as well as

explosive or hazardous substances, we rec-

ommend installing a suitable leakage indica-

tor (e.g. a contact pressure gauge, an outlet

to an open vessel or an inspection glass).

Risk of personal injury due to pressurized

components and process medium escaping

under pressure.

Do not loosen the screw of the test connec

-

tion while the valve is in operation.

Safety guard

To reduce the crush hazard arising from

moving parts (actuator and plug stem), a

safety guard can be installed.

Valve accessories

A mounting kit is required to mount position-

ers, limit switches, solenoid valves or other

valve accessories. The mounting kit (item no.

1400-9031) can be ordered from

SAMSON. Refer to the mounting and oper-

ating instructions of the corresponding de-

vice for a description on how to mount it.

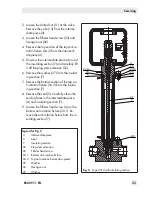

5.2.3 Installing the control

valve

Version with female thread or flanges

1. Close the shut-off valve in the pipeline

while the valve is being installed.

2. Remove the protective caps from the

valve ports before installing the valve.

Note

WARNING

!

Содержание 3510

Страница 29: ...EB 8091 1 EN 29...