16

May 2013

IMO_294_EN_v0

Roto E-Tec DoorDrive

Subject to change.

Installation

Installation steps overview

1.

Preparing profiles (milling, drilling)

2.

Routing lines in profile

3.

Installing swing door drive

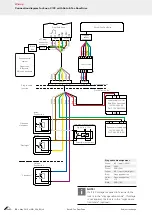

4.

Installing control electronics

5.

Installing door

6.

Conducting function test

7.

Connecting power supply unit and additional peripherals / house wiring

(electrician)

Steps 1 to 4 are conducted at the factory. Steps 5 to 7 are conducted at the

building site or the door installation location.

Preparation

When installing and positioning the door drive and its components in the

door system, process the door profiles in line with the drilling and milling

drawing available from Roto.

If the dimensions and tolerances in the drilling and milling drawing are not

complied with, fault-free operation of the door drive cannot be guaranteed.

Installation problems may also occur.

Mill out corner connector as far as required only. Make a corresponding

corner bracket for reinforcement in the clearance.

Set the control to match the Roto configuration. (Refer to page 31).

This programming step is best performed in advance, e.g. at the factory.

NOTE!

Installation sequence

Install the wiring harness in the door sash before inserting the

door panel.

The drill holes and milling must be conducted in accordance with

the DIN ISO 2768-mK general tolerance.

NOTE!

Precautions should be taken when installing the door to ensure

that any inadvertent opening beyond the maximum opening width

is avoided, as otherwise the swing door drive could be damaged.

An end stop must be fitted for the maximum opening position on

site to ensure that the maximum opening angle (< 105° system

specific) is not exceeded.

NOTE!

Sufficient clearance must be given between the frame and the

sash at each point, as otherwise reliable closing and opening of

the sash cannot be assured.

NOTE!

The sealing systems used must be capable of being sufficiently

compressed to ensure that the sash is reliably closed.