2

1

Flexcut 80 Torch Positioning Procedure

DOC #:7214-0-US70-080818-DS-02-02

Rev#:00

Rev Date:8/8/2018

Proprietary & Confidential: This document contains proprietary information owned by Lincoln Electric Cutting Systems, Inc. and may not be duplicated, communicated to other parties, or used for any

purpose without the express written permission of Lincoln Electric Cutting Systems, Inc.

THIS DOCUMENT IS VALID FOR 24 HOURS AFTER PRINTING – Dated: 6/7/2018

Flexcut 80 Torch Positioning Procedure

Summary:

The purpose of the instructions below are to explain how change the

position of the LC105/100M within the torch holder clamps, per OEM

specification.

Step 1:

Datum the machine.

Step 2:

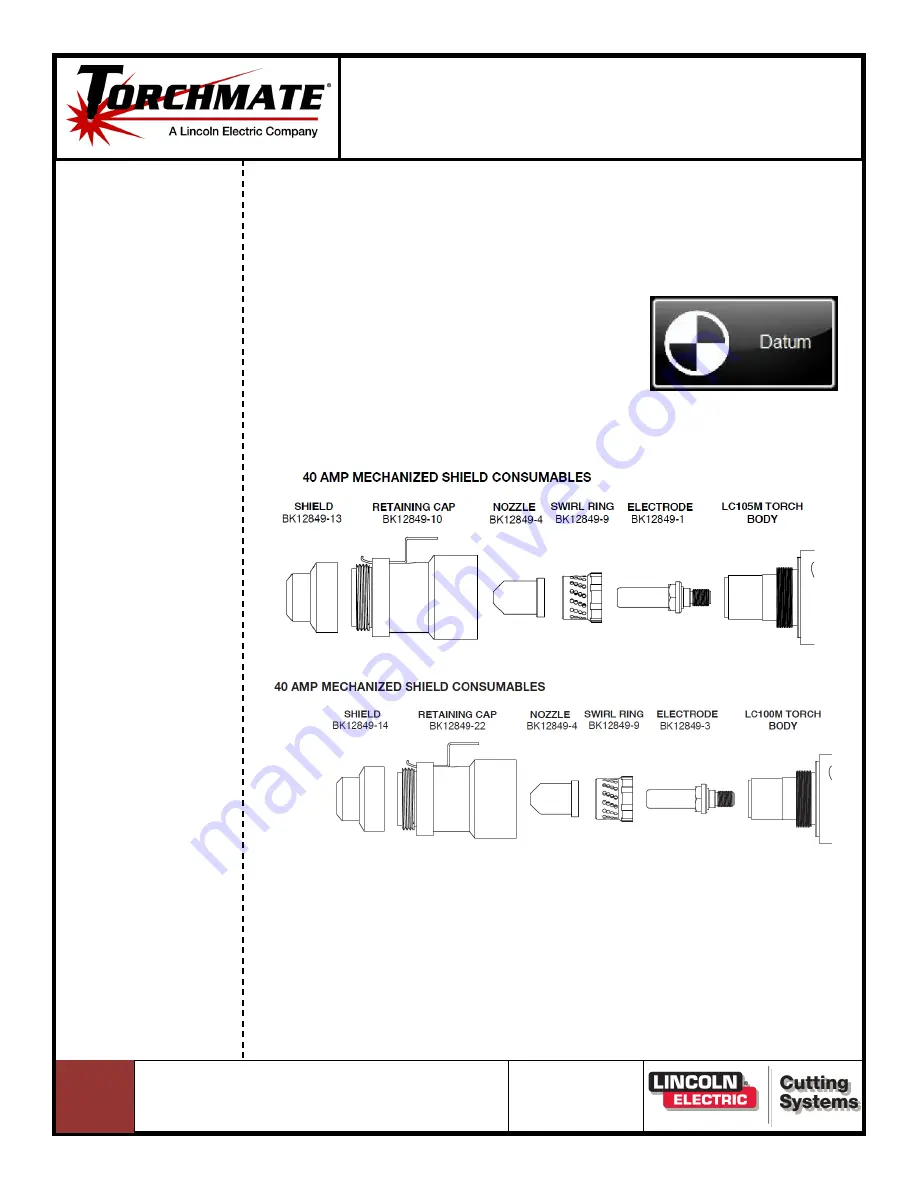

Install the 40 amp consumable stack to the LC105/100M torch.

LC105M:

LC100M:

Step 3:

Jog the machine, in the X and Y axis, to a position between two slats.

Step 4:

Jog the Z axis down to the end of its travel.