2-19

2.

2.

2.

2.

Using the Special Tool

Using the Special Tool

Using the Special Tool

Using the Special Tool

Pressure Gage Assembly

Pressure Gage Assembly

Pressure Gage Assembly

Pressure Gage Assembly

Measuring Fuel and Air Pressure

1.

Mover the lever for cock (3T5

Mover the lever for cock (3T5

Mover the lever for cock (3T5

Mover the lever for cock (3T5----72883

72883

72883

72883----O) to position A shown in the figure below.

O) to position A shown in the figure below.

O) to position A shown in the figure below.

O) to position A shown in the figure below.

2.

Screw adapt

Screw adapt

Screw adapt

Screw adapter B (3T5

er B (3T5

er B (3T5

er B (3T5----72884

72884

72884

72884----0) into either the air or fuel pressure measuring valves located on the air rail.

0) into either the air or fuel pressure measuring valves located on the air rail.

0) into either the air or fuel pressure measuring valves located on the air rail.

0) into either the air or fuel pressure measuring valves located on the air rail.

Caution:

Caution:

Caution:

Caution:

A small amount of fuel will spurt out as the adapter is inserted in the fuel measuring valve.

3.

With the ignition key set the OFF position, turn it to

With the ignition key set the OFF position, turn it to

With the ignition key set the OFF position, turn it to

With the ignition key set the OFF position, turn it to START to activate the starter motor and turn over the

START to activate the starter motor and turn over the

START to activate the starter motor and turn over the

START to activate the starter motor and turn over the

engine for approximately 15 seconds. (Once the engine starts, allow it to idle at 700 rpm for approximately for

engine for approximately 15 seconds. (Once the engine starts, allow it to idle at 700 rpm for approximately for

engine for approximately 15 seconds. (Once the engine starts, allow it to idle at 700 rpm for approximately for

engine for approximately 15 seconds. (Once the engine starts, allow it to idle at 700 rpm for approximately for

15 minutes.)

15 minutes.)

15 minutes.)

15 minutes.)

4.

If both fuel and air pressure values fall within the standard (rated) range,

If both fuel and air pressure values fall within the standard (rated) range,

If both fuel and air pressure values fall within the standard (rated) range,

If both fuel and air pressure values fall within the standard (rated) range, engine operation is

engine operation is

engine operation is

engine operation is

normal. (If not,

normal. (If not,

normal. (If not,

normal. (If not,

service the engine by referring to the relevant sections in this manual.)

service the engine by referring to the relevant sections in this manual.)

service the engine by referring to the relevant sections in this manual.)

service the engine by referring to the relevant sections in this manual.)

PRESSURE

Rated value (kPa, psi)

Rated range (kPa, psi)

Remarks

AIR PRESSURE

550, 80

550

④

30, 80

④

4

FUEL PRESSURE

620, 90

620

④

30, 90④ 4

Pressure falls when engine stops turning

over.

5.

When finished measuring, turn the lever to position B (open) to relieve internal pressure

When finished measuring, turn the lever to position B (open) to relieve internal pressure

When finished measuring, turn the lever to position B (open) to relieve internal pressure

When finished measuring, turn the lever to position B (open) to relieve internal pressure;;;; then remove adapter

then remove adapter

then remove adapter

then remove adapter

B from the measuring valve.

B from the measuring valve.

B from the measuring valve.

B from the measuring valve.

It is important to have a container handy. Once fuel measuring completes and the lever is set to position B (open), a

certain amount of fuel will spurt out from the hose (98AB-5-0200). Be sure to point the hose (98AH-8-1 000) on the cock

side lower than valve position and drain all remaining fuel prior to removing adapter B.

Содержание 40 hp

Страница 3: ......

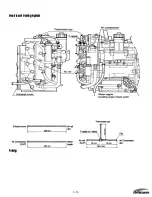

Страница 9: ...1 2 2 O 2 O 2 O 2 Outline Dimensions utline Dimensions utline Dimensions utline Dimensions ...

Страница 17: ...1 10 ...

Страница 19: ...2 2 ...

Страница 20: ...2 1 ...

Страница 35: ...2 16 5 Special Tools 5 Special Tools 5 Special Tools 5 Special Tools ...

Страница 43: ...2 24 ...

Страница 48: ...3 5 ...

Страница 50: ...3 7 ...

Страница 54: ...3 11 ...

Страница 57: ...4 2 1 1 1 1 Power Uni Power Uni Power Uni Power Unit t t t ...

Страница 60: ...4 5 ...

Страница 66: ...4 11 ...

Страница 68: ...4 13 ...

Страница 72: ...4 17 ...

Страница 75: ...4 20 ...

Страница 86: ...4 31 ...

Страница 97: ...4 42 Piston and Crankshaft Piston and Crankshaft Piston and Crankshaft Piston and Crankshaft ...

Страница 106: ...4 51 ...

Страница 111: ...5 2 1 1 1 1 Wire Routing Wire Routing Wire Routing Wire Routing ...

Страница 112: ...5 3 ...

Страница 113: ...5 4 ...

Страница 114: ...5 5 ...

Страница 115: ...5 6 ...

Страница 116: ...5 7 Wiring Diagram 40B 50B EPTO ...

Страница 117: ...5 8 ...

Страница 118: ...5 9 ...

Страница 119: ...5 10 ...

Страница 120: ...5 11 ...

Страница 121: ...5 12 ...

Страница 126: ...5 17 Note Slash shows stripe color of cable 2 2 2 2 Assembly Assembly Assembly Assembly ...

Страница 127: ...5 18 Wiring around solenoid Bracket ...

Страница 128: ...5 19 ...

Страница 129: ...5 20 ...

Страница 130: ...5 21 ...

Страница 136: ...5 27 Kill Switch Crank Sensor Oil Level Sensor Grounds Air Injector 1 ...

Страница 137: ...5 28 Air Injector 2 Air Injector 3 Coil 1 Coil 2 Coil 3 ...

Страница 138: ...5 29 Fuel Pump Fuse Box Regulator Stator Complete Wiring harness ...

Страница 140: ...6 2 1 1 1 1 Configuration Configuration Configuration Configuration GEARCASE DRIVESHAFT ...

Страница 141: ...6 3 GEARCASE PROPELLERSHAFT ...

Страница 152: ...6 14 ...

Страница 153: ...6 15 ...

Страница 185: ...10 20 ...

Страница 193: ...11 8 ...