5

35

Avoid abuse

5-1

Abuse can shorten the life of a wheel. Lack of care in changing a tire, heavy pounding

of the wheel rim, overloading, exposure to excessive heat or hitting curbs at high speed

or a sharp angle can damage wheels.

Do not overinflate. Use the tire manufacturer's recommended pressure, but under

no circumstances exceed cold tire pressures listed in Section 1 Specifications

of this manual. Before mounting the tire perform a wheel fitment check to insure

proper clearance from any obstructions.

Refer to tire manufacturer’s recommendation for proper tire pressure. Before

mounting the tire perform a wheel fitment check to insure proper clearance

from any obstructions.

Wheel cap nuts must be kept tight (see 4-9, page 29). When checking the cap nuts on

dual disc wheels utilizing the stud located ball seat mounting system, loosen every

other outer cap nut and then check the torque of the inner cap nuts. Retorque the

loosened outer cap nuts. Repeat procedure with the rest of the nuts. Check all cap

nuts for proper torque after the first use or any removal. Inspect wheels and check

wheel nuts during service stops. (See Section 2, page 5). Dirt streaks from cap nuts

may indicate looseness.

Flange nuts must be kept tight, and studs and nuts should be checked frequently. At

tire changes nuts and studs should be inspected to be sure they are in good condition.

If nuts require frequent tightening or studs break frequently, hardware and mounting

practices should be reviewed.

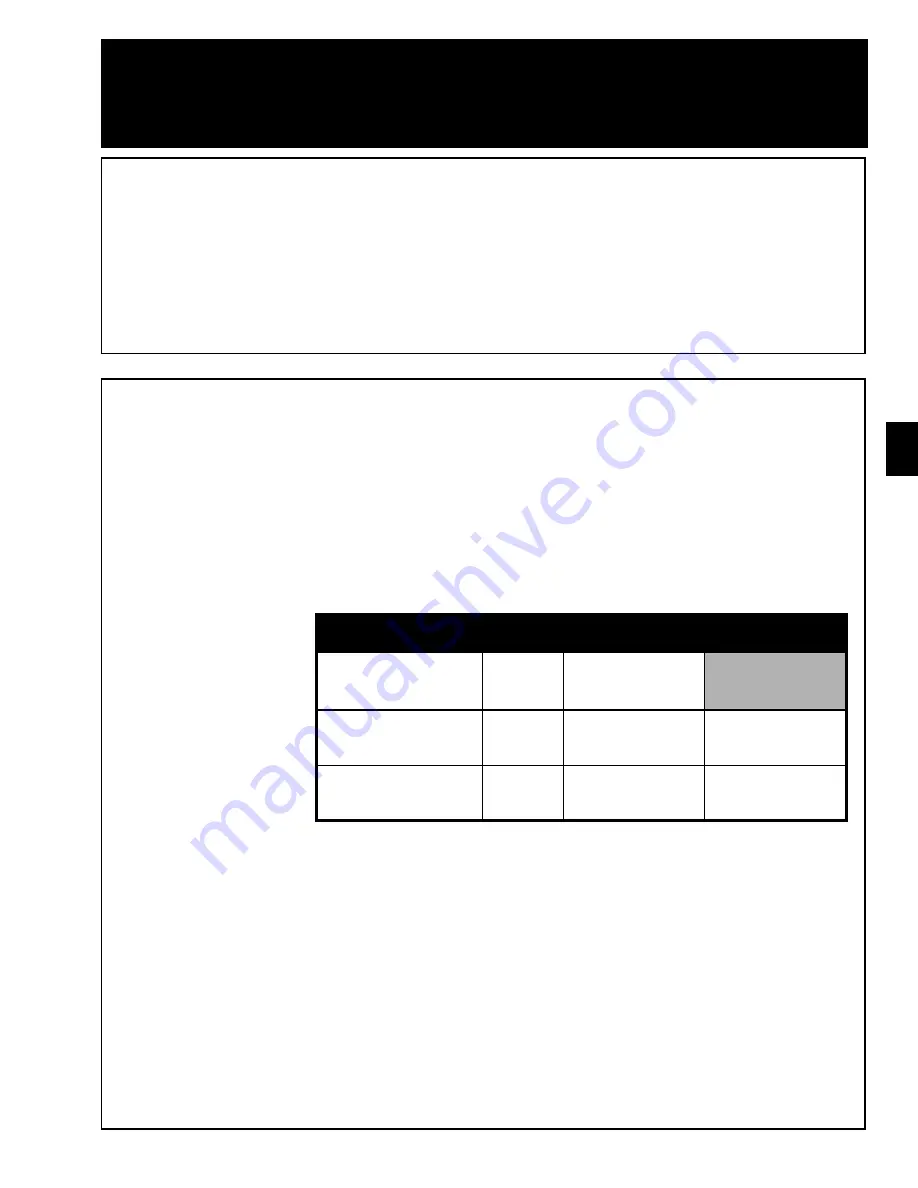

For proper nut torque, refer to the chart below:

Mount

Nut

Torque Level Ft-Lb

Torque Level Ft-Lb

Type

Thread

Lubricated*

Dry*

Hub piloted using

11/16" - 16

300-400

two-piece flange nut

M20 x 1.5

280-330

M22 x 1.5

450-500

Stud piloted, double cap

3/4" - 16

350-400

450-500

nut standard type

1-1/8" - 16

350-400

450-500

(7/8” radius)

Stud piloted, double cap

15/16" - 12

750-900

nut heavy duty type

1-1/8" - 16

650-800

750-900

(1-3/16” radius)

1-5/16" - 12

750-900

*For nuts used on

hub piloted wheels,

apply two drops of oil to the point between the

nut and flange and two drops to the first two or three threads at the tip of each stud

(see 4-11, page 32).

For nuts used on

stud piloted wheels,

apply two drops of oil to the first two or three

threads at the tip of each stud only (see 4-9, page 29).

NOTE:

1.

If using specialty fasteners (cap nuts), consult the manufacturer for recommended

torque values.

2.

Tightening wheel nuts to their specified torque is extremely important.

Undertightening which results in loose wheels can damage wheels, studs and hubs,

and can result in wheel loss. Overtightening can damage studs, nuts and wheels and

results in loose wheels as well.

3.

Regardless of the torque method used, all torque wrenches, air wrenches and any

other tools should be calibrated periodically to ensure the proper torque is applied.

Keep wheel nuts

tight

5-2

Proper Torque, Wheel Identification,

5

Valves and Surface Maintenance

Содержание LE MIRAGE XLII BUS SHELLS

Страница 1: ...COACH MANUFACTURER MAINTENANCE MANUAL LE MIRAGE XLII BUS SHELLS PA1564 1ST EDITION...

Страница 12: ...Section 00 GENERAL INFORMATION 10 PA1564 FIGURE 13 METRIC US STANDARD CONVERSION TABLE 00005...

Страница 13: ...Section 00 GENERAL INFORMATION PA1564 11 FIGURE 14 CONVERSION CHART 00006...

Страница 14: ......

Страница 30: ......

Страница 63: ...SECTION 01 ENGINE PA1564 33 FIGURE 13 POWER PLANT CRADLE INSTALLATION 01140...

Страница 108: ......

Страница 160: ......

Страница 210: ......

Страница 229: ...FAULT CODE MANUAL Created on 00 04 25 15 30 1 FAULT CODE MANUAL B7L B7TL B12...

Страница 254: ......

Страница 281: ......

Страница 282: ......

Страница 283: ......

Страница 284: ......

Страница 285: ......

Страница 286: ......

Страница 287: ......

Страница 288: ......

Страница 289: ......

Страница 290: ......

Страница 291: ......

Страница 292: ......

Страница 303: ...SPICER SPECIALITY AXLE DIVISION place product photo here SERVICE MANUAL GENERAL INFORMATION NDS Axle range BACK RETOUR...

Страница 309: ......

Страница 348: ...Page No 18 Manual No NDS8 Spicer Speciality Axle Division Technical Publications Spicer Speciality Axle Division TP1193...

Страница 379: ...Section 12 BRAKE AND AIR SYSTEM PA1564 21 FIGURE 38 AIR OPERATED BRAKING SYSTEM WE...

Страница 380: ...Section 12 BRAKE AND AIR SYSTEM PA1564 22 FIGURE 39 AIR OPERATED BRAKING SYSTEM W5...

Страница 387: ...Section 12 BRAKE AND AIR SYSTEM PA1564 29 FIGURE 46 ABS 6S 5M CONFIGURATION...

Страница 418: ...16 BW2158 Honeywell Commercial Vehicle Systems Company 4 2001 Printed in USA...

Страница 422: ......

Страница 430: ......

Страница 438: ......

Страница 445: ......

Страница 458: ......

Страница 514: ...48 REVISED 5 31 05 BW2429 2005 Bendix Commercial Vehicle Systems LLC All Rights Reserved 5 05 Printed in U S A...

Страница 534: ......

Страница 540: ......

Страница 543: ......

Страница 596: ...52 9 Inch Fraction Decimal and Millimeter Equivalents Chart Up to 1 inch 9 1 9 Conversion Tables...

Страница 660: ......

Страница 661: ......

Страница 662: ......

Страница 663: ......

Страница 664: ......

Страница 665: ......

Страница 666: ......

Страница 667: ......

Страница 668: ......

Страница 669: ......

Страница 670: ......

Страница 671: ......

Страница 672: ......

Страница 673: ......

Страница 674: ......

Страница 675: ......

Страница 676: ......

Страница 677: ......

Страница 678: ......

Страница 679: ......

Страница 680: ......

Страница 681: ......

Страница 682: ......

Страница 683: ......

Страница 684: ......

Страница 685: ......

Страница 686: ......

Страница 687: ......

Страница 688: ......

Страница 689: ......

Страница 690: ......

Страница 691: ......

Страница 692: ......

Страница 693: ......

Страница 694: ......

Страница 695: ......

Страница 696: ......

Страница 697: ......

Страница 698: ......

Страница 699: ......

Страница 700: ......

Страница 701: ......

Страница 702: ......

Страница 703: ......

Страница 704: ......

Страница 705: ......

Страница 706: ......

Страница 707: ......

Страница 708: ......

Страница 709: ......

Страница 710: ......

Страница 711: ......

Страница 712: ......

Страница 713: ......

Страница 714: ......

Страница 715: ......

Страница 716: ......

Страница 717: ......

Страница 718: ......

Страница 719: ......

Страница 720: ......

Страница 721: ......

Страница 722: ......

Страница 723: ......

Страница 724: ......

Страница 725: ......

Страница 726: ......

Страница 727: ......

Страница 728: ......

Страница 729: ......

Страница 730: ......

Страница 731: ......

Страница 732: ......

Страница 733: ......

Страница 734: ......

Страница 735: ......

Страница 736: ......

Страница 737: ......

Страница 738: ......

Страница 739: ......

Страница 740: ......

Страница 741: ......

Страница 742: ......

Страница 743: ......

Страница 744: ......

Страница 745: ......

Страница 746: ......

Страница 747: ......

Страница 748: ......

Страница 749: ......

Страница 750: ......

Страница 751: ......

Страница 752: ......

Страница 753: ......

Страница 754: ......

Страница 755: ......

Страница 756: ......

Страница 757: ......

Страница 758: ......

Страница 759: ......

Страница 760: ......

Страница 782: ...Section 16 SUSPENSION PA1564 22 FIGURE 26 SWAY BAR FRONT SUSPENSION 16138D FIGURE 27 SWAY BAR REAR SUSPENSION 16014...

Страница 798: ......

Страница 886: ......

Страница 900: ......

Страница 902: ......

Страница 904: ......

Страница 910: ......

Страница 916: ......

Страница 920: ......

Страница 924: ......

Страница 926: ...PROCEDURE NO SAV00044 REVISION 00 Page 2 of 2 Slide out...

Страница 930: ......

Страница 932: ......

Страница 934: ......

Страница 940: ......

Страница 944: ......

Страница 946: ......

Страница 954: ......

Страница 976: ......

Страница 988: ......

Страница 992: ......

Страница 996: ......

Страница 1032: ......

Страница 1038: ......

Страница 1044: ......

Страница 1064: ......

Страница 1083: ...Section 22 HEATING AND AIR CONDITIONING PA1564 15 FIGURE 16 REFRIGERANT CIRCUIT CENTRAL SYSTEM 22247...

Страница 1086: ...Section 22 HEATING AND AIR CONDITIONING PA1564 18 FIGURE 17 DOUBLE SWEEP EVACUATION SET UP...

Страница 1106: ...Section 22 HEATING AND AIR CONDITIONING PA1564 38 FIGURE 39 REFRIGERANT CIRCUIT SMALL SYSTEM 22350...

Страница 1108: ...Section 22 HEATING AND AIR CONDITIONING PA1564 40 FIGURE 42 CENTRAL HEATING SYSTEM COMPONENTS 22338...

Страница 1118: ...Section 22 HEATING AND AIR CONDITIONING PA1564 50 FIGURE 54 HEATER LINE SHUTOFF VALVES WE...

Страница 1119: ...Section 22 HEATING AND AIR CONDITIONING PA1564 51 FIGURE 55 SMALL HEATING SYSTEM COMPONENTS 22337...

Страница 1124: ......

Страница 1125: ...Compressor 62 11052 Rev A WORKSHOP MANUAL for MODEL 05G TWIN PORT COMPRESSOR R...

Страница 1126: ...WORKSHOP MANUAL COMPRESSOR MODEL 05G TWIN PORT...

Страница 1149: ...Compressor 62 11053 Rev B SERVICE PARTS LIST for MODEL 05G TWIN PORT COMPRESSOR 1 2 3 4 5 6 R...

Страница 1177: ......

Страница 1178: ......

Страница 1179: ...1...

Страница 1180: ...2...

Страница 1181: ...3...

Страница 1182: ...4...

Страница 1183: ...5...

Страница 1184: ...6...

Страница 1185: ...7...

Страница 1186: ...8...

Страница 1187: ...9...

Страница 1188: ......

Страница 1205: ...Section 24 LUBRICATION PA1564 5 FIGURE 1 LUBRICATION AND SERVICING POINTS ON INDEPENDENT FRONT SUSPENSION VEHICLES 24036_1...

Страница 1212: ......

Страница 1223: ...Section 26 XLII SLIDE OUT PA1564 11...

Страница 1224: ...Section 26 XLII SLIDE OUT PA1564 12 FIGURE 16 KEYLESS BUSHING INSTALLATION INSTRUCTION...