2

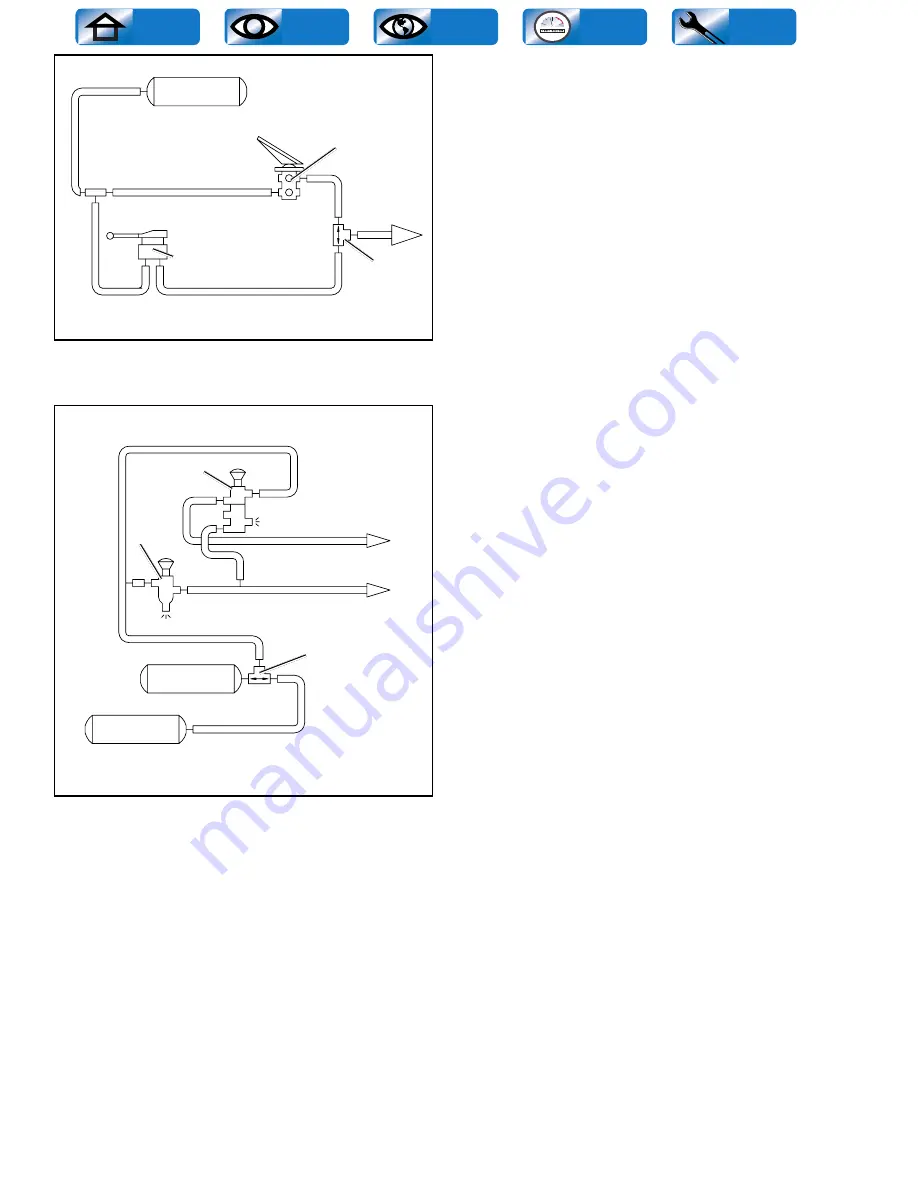

Reservoir

Brake Valve

Trailer Hand

Control Valve

3. Apply and hold a full foot brake valve application.

Check exhaust port of Trailer Control Valve for leakage

with soap solution. Permissible leakage is a one inch

bubble in five seconds (100 sccm). (

Note

: On some

vehicles, an exhaust line is connected to the exhaust

port and piped outside the cab in which case it may

be necessary to disconnect this line to make leakage

check.)

B. If Double Check Valve is to be bench tested or tested on

the vehicle, two separately controlled air supplies must

be connected to the inlet ports.

1. Install an accurate test gauge in the outlet port or in

a line from outlet port.

2. Apply and release air to one inlet port and note that

gauge registers application and release.

3. Repeat by applying and releasing air to other inlet

port.

4. Leakage check should be performed at inlet ports of

valve in the following manner:

a.

Disconnect line from one inlet port.

b.

Apply air to other inlet port and coat opposite

inlet port with soap solution. Permissible leakage is

a one inch bubble in five seconds (100 sccm).

c.

Repeat Step b applying air to other inlet port

while checking opposite inlet port for leakage.

If the Double Check Valve does not function as described or

if leakage is excessive, it is recommended that the valve be

repaired or replaced with genuine Bendix parts. The follow-

ing instructions should prove helpful:

DISASSEMBLY

1. Remove end cap(s) from valve.

2. Remove grommets (if applicable).

3. Remove shuttle and/or shuttle guide, disc and/or disc

guide (depending upon type of valve).

CLEANING AND INSPECTION

1. Clean all metal parts in a cleaning solvent.

2. Inspect all metal parts for signs of cracks, wear or dete-

rioration. Replace all parts not considered serviceable.

3. Replace all rubber parts.

ASSEMBLY

1. Install disc guide, disc and/or shuttle and shuttle guide.

2. Coat all static seals such as o-rings, grommets, etc.

with BW 650M Silicone lubricant (BW 291126). It is not

necessary to lubricate shuttles or discs.

3. Install grommets.

4. Install end cap(s).

TESTING OF REBUILT DOUBLE CHECK VALVE

SERVICE CHECKS

OPERATING AND LEAKAGE TEST

A. When the Double Check Valve is used in conjunction

with a Trailer Control Valve, the following operating and

leakage test can be made:

1. Apply and release foot brake valve and note that the

brakes apply and release on both tractor and trailer.

2. Apply and release the Trailer Control Valve and note

that only the trailer brakes apply and release. With

trailer control valve applied check exhaust port of

foot brake valve for leakage with soap solution.

Permissible leakage is a one inch bubble in five

seconds (100 sccm).

Reservoir

Reservoir

Trailer Supply

Spring Brake Control

Double Check

Valve

FIGURE 4 -

DOUBLE CHECK VALVE: SYSTEM WITH TWO

SUPPLY SOURCES

PP-7

PP-1

FIGURE 3 -

DOUBLE CHECK VALVE: CONTROL OF

SYSTEM FROM EITHER OF TWO CONTROL SOURCES

Double

Check

Valve

To Trailer

Brakes

Содержание LE MIRAGE XLII BUS SHELLS

Страница 1: ...COACH MANUFACTURER MAINTENANCE MANUAL LE MIRAGE XLII BUS SHELLS PA1564 1ST EDITION...

Страница 12: ...Section 00 GENERAL INFORMATION 10 PA1564 FIGURE 13 METRIC US STANDARD CONVERSION TABLE 00005...

Страница 13: ...Section 00 GENERAL INFORMATION PA1564 11 FIGURE 14 CONVERSION CHART 00006...

Страница 14: ......

Страница 30: ......

Страница 63: ...SECTION 01 ENGINE PA1564 33 FIGURE 13 POWER PLANT CRADLE INSTALLATION 01140...

Страница 108: ......

Страница 160: ......

Страница 210: ......

Страница 229: ...FAULT CODE MANUAL Created on 00 04 25 15 30 1 FAULT CODE MANUAL B7L B7TL B12...

Страница 254: ......

Страница 281: ......

Страница 282: ......

Страница 283: ......

Страница 284: ......

Страница 285: ......

Страница 286: ......

Страница 287: ......

Страница 288: ......

Страница 289: ......

Страница 290: ......

Страница 291: ......

Страница 292: ......

Страница 303: ...SPICER SPECIALITY AXLE DIVISION place product photo here SERVICE MANUAL GENERAL INFORMATION NDS Axle range BACK RETOUR...

Страница 309: ......

Страница 348: ...Page No 18 Manual No NDS8 Spicer Speciality Axle Division Technical Publications Spicer Speciality Axle Division TP1193...

Страница 379: ...Section 12 BRAKE AND AIR SYSTEM PA1564 21 FIGURE 38 AIR OPERATED BRAKING SYSTEM WE...

Страница 380: ...Section 12 BRAKE AND AIR SYSTEM PA1564 22 FIGURE 39 AIR OPERATED BRAKING SYSTEM W5...

Страница 387: ...Section 12 BRAKE AND AIR SYSTEM PA1564 29 FIGURE 46 ABS 6S 5M CONFIGURATION...

Страница 418: ...16 BW2158 Honeywell Commercial Vehicle Systems Company 4 2001 Printed in USA...

Страница 422: ......

Страница 430: ......

Страница 438: ......

Страница 445: ......

Страница 458: ......

Страница 514: ...48 REVISED 5 31 05 BW2429 2005 Bendix Commercial Vehicle Systems LLC All Rights Reserved 5 05 Printed in U S A...

Страница 534: ......

Страница 540: ......

Страница 543: ......

Страница 596: ...52 9 Inch Fraction Decimal and Millimeter Equivalents Chart Up to 1 inch 9 1 9 Conversion Tables...

Страница 660: ......

Страница 661: ......

Страница 662: ......

Страница 663: ......

Страница 664: ......

Страница 665: ......

Страница 666: ......

Страница 667: ......

Страница 668: ......

Страница 669: ......

Страница 670: ......

Страница 671: ......

Страница 672: ......

Страница 673: ......

Страница 674: ......

Страница 675: ......

Страница 676: ......

Страница 677: ......

Страница 678: ......

Страница 679: ......

Страница 680: ......

Страница 681: ......

Страница 682: ......

Страница 683: ......

Страница 684: ......

Страница 685: ......

Страница 686: ......

Страница 687: ......

Страница 688: ......

Страница 689: ......

Страница 690: ......

Страница 691: ......

Страница 692: ......

Страница 693: ......

Страница 694: ......

Страница 695: ......

Страница 696: ......

Страница 697: ......

Страница 698: ......

Страница 699: ......

Страница 700: ......

Страница 701: ......

Страница 702: ......

Страница 703: ......

Страница 704: ......

Страница 705: ......

Страница 706: ......

Страница 707: ......

Страница 708: ......

Страница 709: ......

Страница 710: ......

Страница 711: ......

Страница 712: ......

Страница 713: ......

Страница 714: ......

Страница 715: ......

Страница 716: ......

Страница 717: ......

Страница 718: ......

Страница 719: ......

Страница 720: ......

Страница 721: ......

Страница 722: ......

Страница 723: ......

Страница 724: ......

Страница 725: ......

Страница 726: ......

Страница 727: ......

Страница 728: ......

Страница 729: ......

Страница 730: ......

Страница 731: ......

Страница 732: ......

Страница 733: ......

Страница 734: ......

Страница 735: ......

Страница 736: ......

Страница 737: ......

Страница 738: ......

Страница 739: ......

Страница 740: ......

Страница 741: ......

Страница 742: ......

Страница 743: ......

Страница 744: ......

Страница 745: ......

Страница 746: ......

Страница 747: ......

Страница 748: ......

Страница 749: ......

Страница 750: ......

Страница 751: ......

Страница 752: ......

Страница 753: ......

Страница 754: ......

Страница 755: ......

Страница 756: ......

Страница 757: ......

Страница 758: ......

Страница 759: ......

Страница 760: ......

Страница 782: ...Section 16 SUSPENSION PA1564 22 FIGURE 26 SWAY BAR FRONT SUSPENSION 16138D FIGURE 27 SWAY BAR REAR SUSPENSION 16014...

Страница 798: ......

Страница 886: ......

Страница 900: ......

Страница 902: ......

Страница 904: ......

Страница 910: ......

Страница 916: ......

Страница 920: ......

Страница 924: ......

Страница 926: ...PROCEDURE NO SAV00044 REVISION 00 Page 2 of 2 Slide out...

Страница 930: ......

Страница 932: ......

Страница 934: ......

Страница 940: ......

Страница 944: ......

Страница 946: ......

Страница 954: ......

Страница 976: ......

Страница 988: ......

Страница 992: ......

Страница 996: ......

Страница 1032: ......

Страница 1038: ......

Страница 1044: ......

Страница 1064: ......

Страница 1083: ...Section 22 HEATING AND AIR CONDITIONING PA1564 15 FIGURE 16 REFRIGERANT CIRCUIT CENTRAL SYSTEM 22247...

Страница 1086: ...Section 22 HEATING AND AIR CONDITIONING PA1564 18 FIGURE 17 DOUBLE SWEEP EVACUATION SET UP...

Страница 1106: ...Section 22 HEATING AND AIR CONDITIONING PA1564 38 FIGURE 39 REFRIGERANT CIRCUIT SMALL SYSTEM 22350...

Страница 1108: ...Section 22 HEATING AND AIR CONDITIONING PA1564 40 FIGURE 42 CENTRAL HEATING SYSTEM COMPONENTS 22338...

Страница 1118: ...Section 22 HEATING AND AIR CONDITIONING PA1564 50 FIGURE 54 HEATER LINE SHUTOFF VALVES WE...

Страница 1119: ...Section 22 HEATING AND AIR CONDITIONING PA1564 51 FIGURE 55 SMALL HEATING SYSTEM COMPONENTS 22337...

Страница 1124: ......

Страница 1125: ...Compressor 62 11052 Rev A WORKSHOP MANUAL for MODEL 05G TWIN PORT COMPRESSOR R...

Страница 1126: ...WORKSHOP MANUAL COMPRESSOR MODEL 05G TWIN PORT...

Страница 1149: ...Compressor 62 11053 Rev B SERVICE PARTS LIST for MODEL 05G TWIN PORT COMPRESSOR 1 2 3 4 5 6 R...

Страница 1177: ......

Страница 1178: ......

Страница 1179: ...1...

Страница 1180: ...2...

Страница 1181: ...3...

Страница 1182: ...4...

Страница 1183: ...5...

Страница 1184: ...6...

Страница 1185: ...7...

Страница 1186: ...8...

Страница 1187: ...9...

Страница 1188: ......

Страница 1205: ...Section 24 LUBRICATION PA1564 5 FIGURE 1 LUBRICATION AND SERVICING POINTS ON INDEPENDENT FRONT SUSPENSION VEHICLES 24036_1...

Страница 1212: ......

Страница 1223: ...Section 26 XLII SLIDE OUT PA1564 11...

Страница 1224: ...Section 26 XLII SLIDE OUT PA1564 12 FIGURE 16 KEYLESS BUSHING INSTALLATION INSTRUCTION...