Chapter 5 Commissioning operation

ADSD-S-S

49

5-2-9 The position control the gain

paramet

ers

designation

range

default

value

unit

apply

L009

position loop gain

1

~

1000

40

1/s

P

L021

Position loop

feed forward

gain

0

~

100

0

%

P

L022

Position loop feed forward

filtering time constant

0.20

~

50.00

1.00

ms

P

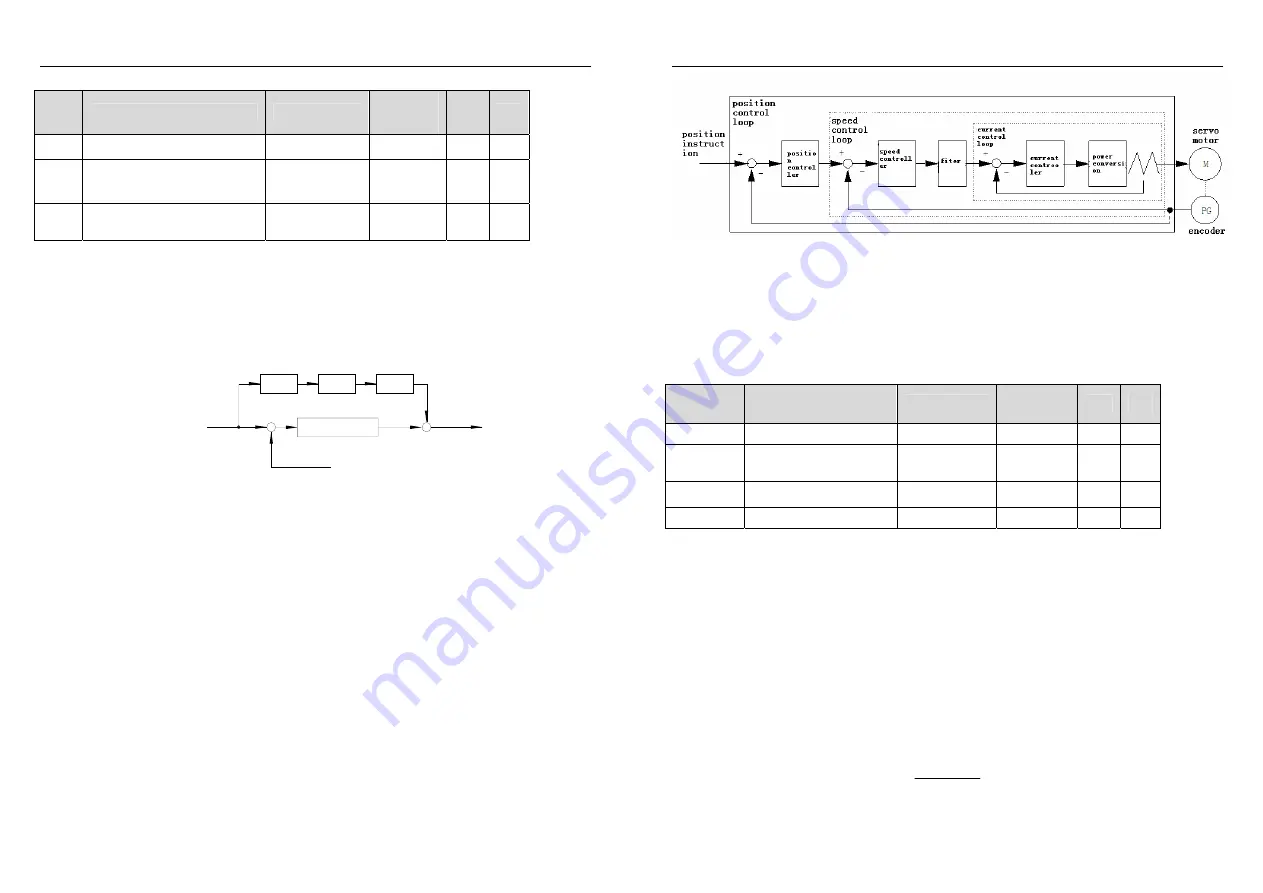

Because the position loop including speed loop, in accordance with the outer after inner ring

order, first set up load than inertia, then adjust speed loop gain and speed loop integral time constant,

finally change position loop gain.

The following is the position

controller

system,

i

ncreases the

position loop gain K

can improve

the position loop bandwidth, but being limited by the speed loop bandwidth. So want to increase the

position loop gain that must

improve the speed loop bandwidth at the first.

differential

L021

L022

position loop gain (

Kp)

+speed

instruction

position

instruction

+

-

position

feedback

+

F

eed forward

can reduce the position loop control phase lag, can reduce the position control

position tracking error and the less time of the orientation. F

eed forward

volume increasing and the

position control the tracking error decreasing, but too big would make the system unstable and

overshoot. If the electronic gear ratios are greater than 10 also easy to

produce

noise. Application

can set the L021as 0%,when need high response and low tracking error, can appropriately increased

and not more than 80%, also need to adjust the position loop f

eed forward

filtering time

constant(parameters L022).

5-2-10 Gain adjustment

Drive including current control ring, speed control loop and the position control ring three

control circuit, follow the control diagram:

Chapter 5 Commissioning operation

ADSD-S-S

50

In the abstract, the inner control circuit of the bandwidth must be higher than the outer layer,

otherwise the whole control system would not be stable that may cause vibration or response not

better, so the three control loop bandwidth relationship as follows:

Current loop bandwidth>Speed loop bandwidth>Position loop bandwidth.

Since drive has been adjusted for the current control loop well, so that users simply adjust

speed control loop and the position control ring parameters

.

1.

Gain parameters

Gain relevant parameters:

parameters

designation

range

default

value

unit apply

L005

Speed loop gain

1

~

3000

40

Hz

P

L006

Speed loop integral time

constant

1.0

~

1000.0

20.0

ms P

L009

position loop gain

1

~

1000

40

1/s

P

L017

Load than inertia

0.0

~

200.0

1.5

倍

P

Symbols defined as follows:

K

V

: Speed loop gain;

T

i

: Speed loop integral time constant;

K

p

: P

osition loop gain;

G: Load inertia ratio

(

L017);

J

L

: Inertia converts to the motor shaft load;

J

M

: Motor rotor rotating inertia.

1).Speed loop gain K

V

Speed loop gain K

V

directly

decide

the response of the speed loop bandwidth .In the premise

that the mechanical systems do not produce vibration or noise, increasing velocity gain value, the

speed response can accelerate faster, the peed command following is the better. But too big set was

easy to cause mechanical resonance. Speed loop bandwidth shows as:

)

(

*

/

1

1

z

bandwidth

loop

speed

the

Hz

K

J

J

G

H

V

M

L

+

+

=

)

(

If the load inertia ratio is right, so that speed loop bandwidth equals speed loop gain K

V .