9

8.1.

Installation of hydraulic part

•

Thorough washing of the system with clean water filling and emptying it many times. This

operation allows to riduce the number of maintenances and avoid damages to exchangers and

other components.

•

Test of possible losses in the circuit;

•

Insulate all the pipelines to reduce heat losses and avoid the formation of condensation;

•

Free up the service points like wells vents etc...;

•

Verify that the quality of the water is suitable, contrary:

performance penalty, higher loading losses, possible damages

If there is the risk of water freezing in the system take the following preventive measures:

•

Always powered machine for frost protection.

•

Mix water with ethylene glycol or propylene glycol considering that the pressure losses

increse and you have to verufy the compatibility of all the hydraulic parts of all these

compounds.

•

In case of long stops completely empty the system opening all the cocks and pay attention to

avoid water stagnation points.

8.2.

Correct refilling of the heating system

During the operation of the heat pump system a pressure drop in the heating system can occur. The

reason is often leaking air that has not been removed completely at the initial operation.

If the pressure of the heating system falls under 1.5 bar replenishment is necessary.

IMPORTANT

The replenishment must be done exclusively with treated

heating water. The treatment must be carried out according to

the applicable national standards, regulations and guidelines!

Fill water into the heating system until the manometer on the

connection group displays 2.2 bar.

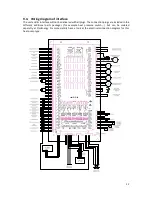

9.

Electrical connections

9.1.

General Information

CAUTION

Before starting work, disconnect the power supply to the system, ensure that no voltage is present

and safeguard against unintentional reconnection. Work on electrical systems may only be carried

out by authorised and trained electricians.

Firstly, ensure that the power supply from the building was correctly relayed to the installation site

and that the cable cross-section is adequate for the starting current and operating current.

Check that all electrical connections are tight. It is essential to ensure that the voltage connected for

the supply matches the voltage that the machine is designed for.