User Manual

E727T0005, valid for E-727

BRO, 2019-06-28

Physik Instrumente (PI) GmbH & Co. KG, Auf der Roemerstrasse 1, 76228 Karlsruhe, Germany

Page 214 / 240

Phone +49 721 4846-0, Fax +49 721 4846-1019, Email

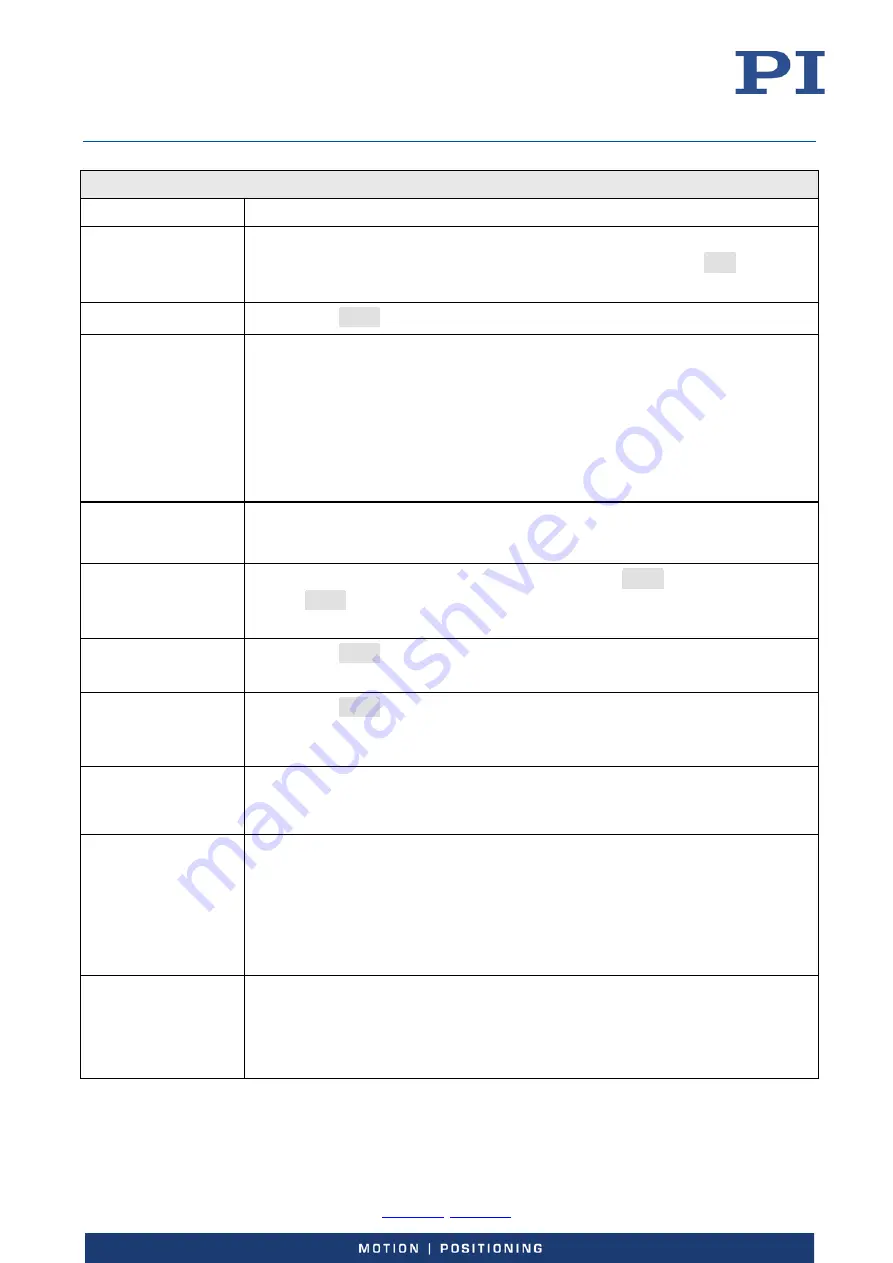

Fault: Stage does not move

Possible Causes

Solution

The stage has been

connected to the

switched-on E-727

The ID chip of the stage has not been read out.

Switch the E-727 off and on again, or reboot the E-727 with the

RBT

command

or with the corresponding functions of the PC software.

E-727 is defective

Send the

ERR?

command and check the error code this returns.

Stage or stage cable is

defective

If available, replace the defective stage with a different stage of the same type

and test the new combination (only possible with stages which are equipped

with ID-chips).

Prevent damage to the stage as follows:

Prevent the stage from exceeding the maximally permissible operating

frequency, e.g. by using suitable waveforms with the wave generator output.

Prevent the stage from oscillating by suitably setting the control parameters.

High-voltage output of

the E-727 is deactiva-

ted due to overheating

Overheating of the E-727

See “Overtemp Protection” (p. 39) for possible measures.

Incorrect configuration

Check the parameter settings of the E-727 with the

SPA?

(volatile memory)

and

SEP?

(nonvolatile memory) commands or in the

Device Parameter

Configuration

window of PIMikroMove.

Incorrect command or

incorrect syntax

Send the

ERR?

command and check the error code this returns.

Make sure that the used motion commands match the operating mode (p. 30).

Motion commands or

wave generator

output are ignored.

Send the

ERR?

command and check the error code this returns.

Observe that only one control source can be used at a time; see "Control Value

Generation" (p. 30).

Incorrect axis

commanded

An axis identifier is even required in commands on systems with only one axis.

Make sure that the correct axis identifier (p. 22) is used and that the

commanded axis belongs to the correct stage.

In the case of analog

control, there is no

connection between

the axis and the

analog input.

When the analog input is used as control source and the axis motion is stopped with

STP or #24, the behaviour depends on the value of the

Disconnect Analog Target

Input When Stopping

parameter (ID 0x0E001E00): 1 = the analog input channel is

disconnected from the axis; 0 = the analog input channel remains connected to the

axis.

If necessary: Reconnect the corresponding input signal channel to the axis.

Further information see "Using the Analog Input" (p. 85).

Sensor zero point is

not set correctly

Changes in temperature or changes in the mechanical load can cause small

deviations of the sensor zero point. When the sensor zero point is not set correctly,

the complete output voltage range of the amplifier cannot be used in closed-loop

operation.

Start an AutoZero procedure (p. 62).