User Manual

E727T0005, valid for E-727

BRO, 2019-06-28

Physik Instrumente (PI) GmbH & Co. KG, Auf der Roemerstrasse 1, 76228 Karlsruhe, Germany

Page 177 / 240

Phone +49 721 4846-0, Fax +49 721 4846-1019, Email

Cyclic Synchronous Position Mode

In Cyclic Synchronous Position mode (CSP), the dynamics profile is calculated by the EtherCAT

master.

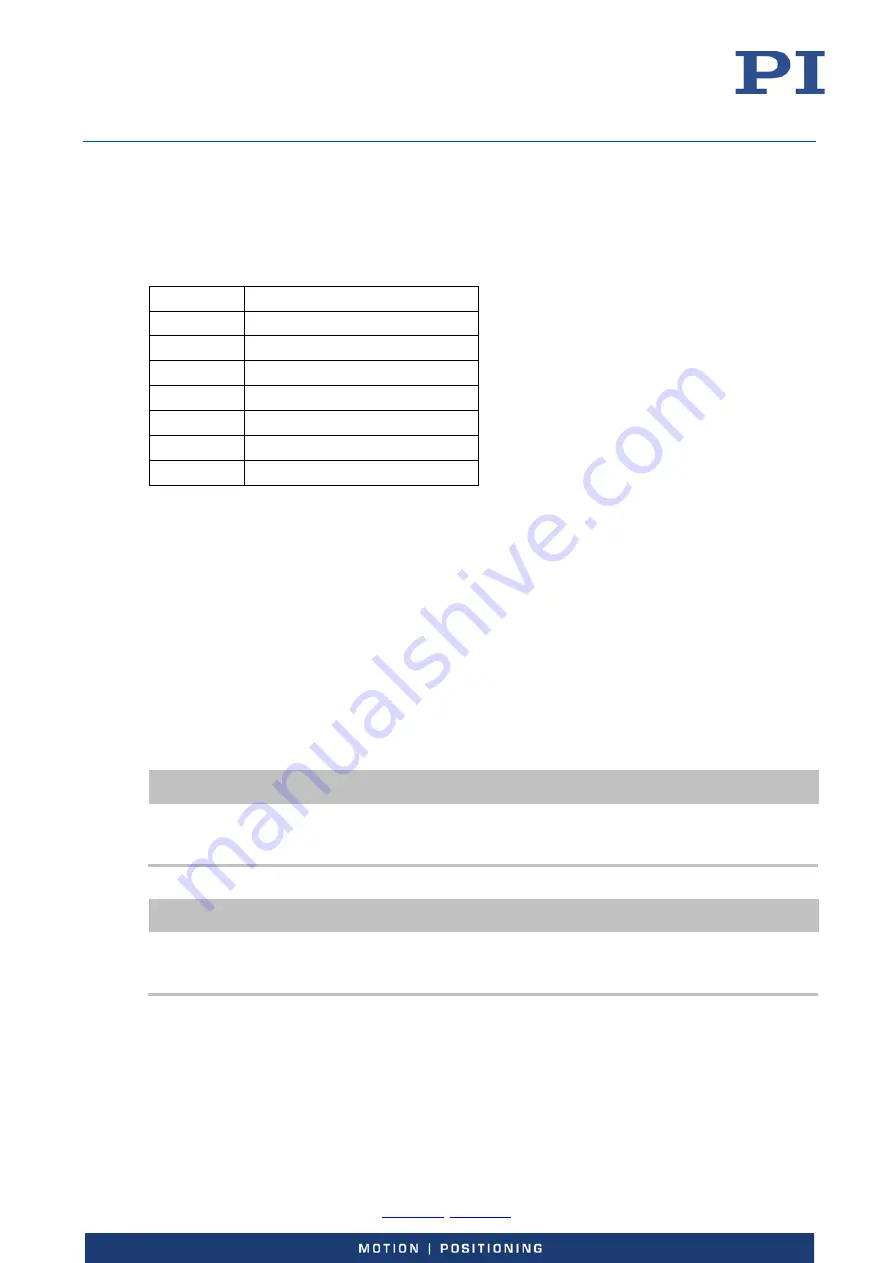

Supported objects (per axis):

Index*

Name

0x6040

Control word

0x6041

Status word

0x6064

Position actual value

0x607A

Target position

0x6060

Modes of operation

0x6061

Modes of operation display

0x60F4

Following error actual value

* Index for the first axis. Note that the object index is shifted by 0x800 per axis, e.g. the index of

the status word for the second axis is 0x6841.

The operation-mode-specific bits 4 to 6 and bit 8 of the control word are ignored in CSP.

The following error actual value (object 0x60F4) is calculated by the E-727 as the difference of

target and actual position.

In CSP the new target position is given cyclically by the EtherCAT master. Bit 10 of the status word

is therefore used as status-toggle information to indicate if the EtherCAT master provides updated

input data. The bit is toggled between 0 and 1 with every update of the input process data.

Bit 12 of the status word in CSP is set if the axis is in the

Operation enabled

state and follows the

target values of the EtherCAT master. In all other cases it is 0 (= target position ignored).

Bit 13 of the status word is always 0.

INFORMATION

The unit of the position values is set via the

FieldbusAxis Resolution

parameter (ID 0x10000800)

of the E-727 and the scaling factor numerator of the EtherCAT master. The values must be

identical. For further details, see p. 165.

INFORMATION

Optimization of digital filter settings (p. 27) and tuning of the servo parameters (p. 134) can

improve the settling behaviour and reduce position noise of the axes. Optimization must be done

via the TCP/IP or USB interface.