Figure 7.33 :

Sprocket removal

7.13 HYDRAULICS

7.13.1 Hydraulics oil

The oil level is monitored by the control unit. An alarm stating “oil level - low” is displayed in the control

unit. Top up if necessary. The oil level can also be visually checked through an oil glass placed in/on the oil

tank.

Check the oil-condition: Minimum once a year.

Change oil: Minimum every third year. See specifications in

Oil-filter: 3 pcs, must be changed minimum once a year and after the first 50 hours of operation (break-in

period).

7.13.2 Hoses and connections

Check the hydraulic system for any leakages, and that no hoses are rubbing against sharp edges on the

machine.

NOTE: The hydraulic hoses have a limited life time. We recommend to change the hydraulic hoses every six

years.

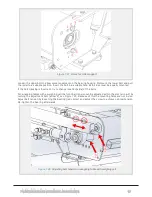

7.13.3 Hydraulic pump, gearbox

Check the input shaft and its splines. Check the bolts holding the gearbox, and retighten if necessary.

Check the oil level in gearbox, with the dipstick.

7 MAINTENANCE AND MECHANICAL ADJUSTMENTS

91

Содержание Dens-X Compactor

Страница 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Страница 102: ...8 6 4 Gearbox and gears for hydraulic motors Gear oil Renolin unisyn CLP 220N 8 LUBRICATION 102...

Страница 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Страница 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Страница 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

Страница 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Страница 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Страница 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Страница 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Страница 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Страница 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Страница 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Страница 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Страница 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

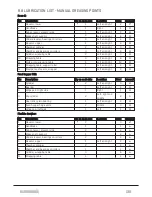

Страница 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

Страница 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Страница 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Страница 142: ...M Maintenance 13 69 71 INDEX 142...