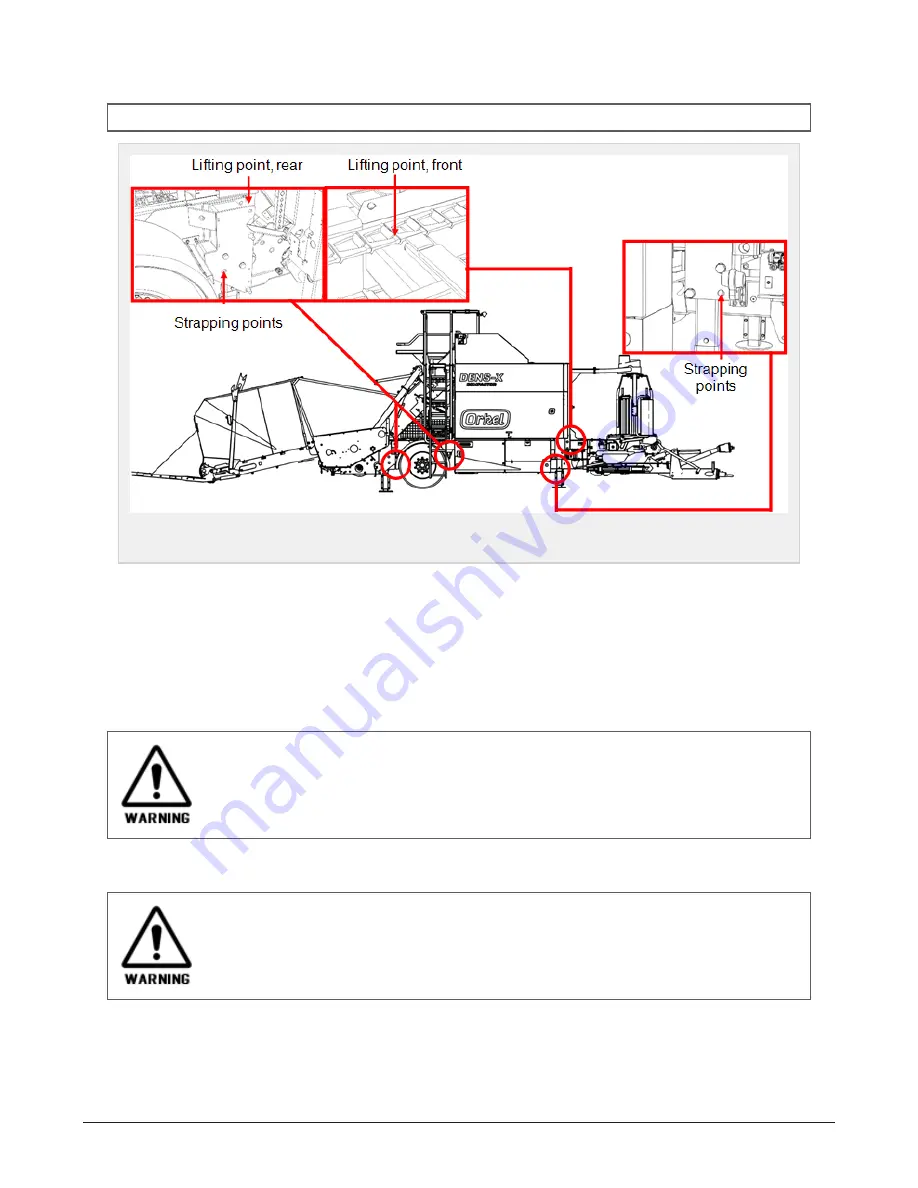

Front: Use a nylon strap to make a loop around the front crossbeam (Beam Dim: 100 x 100mm).

Rear: Use lifting points on the hydraulic jack stands

NOTE: Use only certified lifting gear with sufficient lifting capacity.

Figure 5.1 :

Lifting and strapping points

5.1.4 Strapping and tie down

Secure the machine from moving if transported by lorry, train or boat. Only use approved securing straps

or chains, designed for this purpose. There are four points designed for strapping. One on each hydraulic

jack stand.

5.1.5 Dismantling the machine

General safety precautions must be taken when stripping down the machine. Center of gravity

might change during dismantling. Secure large parts to reduce the risk of injury. Be aware of

overturning.

Hazardous waste like: Oil, plastic and so on, must be stored in an environmentally safe way, or delivered at

a certified waste-disposal plant.

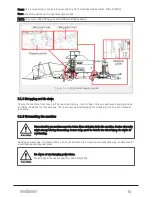

Be aware of overhanging power lines.

Max height in transport position: 3900 mm [F25]

5 TRANSPORT

52

Содержание Dens-X Compactor

Страница 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Страница 102: ...8 6 4 Gearbox and gears for hydraulic motors Gear oil Renolin unisyn CLP 220N 8 LUBRICATION 102...

Страница 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Страница 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Страница 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

Страница 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Страница 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Страница 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Страница 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Страница 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Страница 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Страница 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Страница 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Страница 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

Страница 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

Страница 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Страница 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Страница 142: ...M Maintenance 13 69 71 INDEX 142...