58

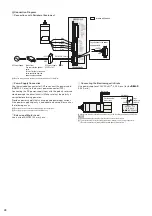

As illustrated below, the parameters listed below are required

when selecting an actuator for transporting a load from A to B.

B

A

Guide

Load

The required parameters are as follows:

●

Mass of load (

m

) or thrust force (

F

)

●

Positioning distance (

L

)

●

Positioning time (

T

)

Among the parameters above, the thrust force and positioning

time can be calculated using the equations below.

■

Calculate the Thrust Force

①

Calculate the thrust force required when accelerating the load.

F

a

=

m

a

+

g

(

sin

θ

+

μ

·

cos

θ

)

②

Calculate the thrust force that allows for pushing and pulling.

F

=

F

max

−

F

a

If the external force of the load is smaller than

F

, push and pull

are possible.

F

max

: Max. thrust force of the actuator [N]

F

a

: Required thrust force during acceleration/deceleration operation [N]

F

: Thrust force that allows for pushing or pulling of external force [N]

m

: Load mass [kg]

a

: Acceleration [m/s

2

]

g

: Gravitational acceleration

9.807

[m/s

2

]

μ

: Friction coefficient of the guide supporting the load

0.01

θ

: Angle formed by the traveling direction and the horizontal plane [˚]

θ

External force

■

Calculate the Positioning Time

Check whether the actuator can perform the necessary

positioning within the specified time. This can be done by

obtaining a rough positioning time from the graph or by obtaining

an accurate positioning time by calculation. The respective

check procedures are explained below.

The actual operating time is subject to a small margin of error, so

use the calculation only as a reference.

●

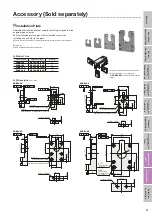

Obtaining from a Graph

Example) Check the positioning time when you provisionally

select the

DRL42G-04A2P-KD

and drive a transport mass of 5

kg vertically a traveling amount of 40 mm. Check that the required

specifications are within the product's specification values.

Check the graph of

DRL42

positioning distance — positioning

time.

1.0

0

0.5

1.5

2.0

2.5

3.5

3.0

4.0

0

40

30

50

60

90

70

80

100

10

20

Positioning Distance

[mm]

Positioning Time

[s

]

Standard Motor, Lead

2 mm

Based on the above graph, it can be verified that the load can be

positioned over 40 mm within 1.5 seconds.

●

Obtaining by Calculations

①

Check the operating conditions.

Check the following conditions:

Installation direction, load mass, positioning distance, starting

speed, acceleration, operating speed

②

From the above operating conditions, check whether the drive

pattern is the triangular drive or trapezoidal drive.

For the triangular drive, calculate the max. speed from the

positioning distance, starting speed, acceleration and operating

speed. If the calculated max. speed is below the operating

speed, the drive pattern will be a triangular drive. If the calculated

max. speed exceeds the operating speed, the drive pattern will

be a trapezoidal drive.

a

1

+

a

2

2

·

a

1

·

a

2

·

L

=

V

R

max

V

R

max

V

R

max

=

·

10

3

+

Vs

2

>

V

R

→

Triangular Drive

V

R

→

Trapezoidal Drive

③

Calculate the positioning time.

<Trapezoidal Drive>

=

T

1

+

T

2

+

T

3

=

+

T

V

R

−

V

S

a

1

×

10

3

V

R

−

V

S

a

2

×

10

3

2

×

a

1

×

a

2

×

V

R

×

10

3

+

−

L

V

R

(

a

1

+

a

2

)

×

(

V

R

2

−

V

S

2

)

<Triangular Drive>

=

T

1

+

T

2

+

T

V

Rmax

−

V

S

V

Rmax

−

V

S

a

1

×

10

3

a

2

×

10

3

=

a

1

a

2

T

T

T

3

T

2

T

2

T

1

T

1

a

1

a

2

V

S

V

Rmax

V

S

V

R

<Pattern 1>

<Pattern 2>

Speed

Time

Speed

Time

Trapezoidal

Drive

Triangular

Drive

V

Rmax

: Calculated max. speed of triangular drive [mm/s]

V

R

: Operating speed [mm/s]

V

s

: Starting speed [mm/s]

T

: Positioning time [s]

L

: Positioning distance [mm]

T

1

: Acceleration time [s]

a

1

: Acceleration [m/s

2

]

T

2

: Deceleration time [s]

a

2

: Deceleration [m/s

2

]

T

3

: Constant speed time [s]

Selection Calculation