Section 3 Pre-Installation Information

The installation instructions in this manual are written for a typical installation. Due to the flexibility of the

system and the unique nature of every site, it is not possible to show every potential installation scenario.

Local codes may dictate specific installation requirements. Installation is subject to approval by jurisdictional

authorities at the site of installation. See Safety Precautions at the beginning of this manual.

If you have a QR code scanner/reader app for your smartphone you can scan this code to view the

instructional video,

PV100

®

Installation and Startup

. If you are viewing this manual on a computer or

tablet, simply click on the code.

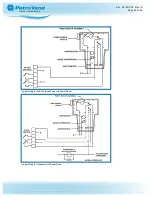

3.1 Conduit/Wiring Requirements

IMPORTANT:

All wiring and conduit runs must conform to the National Electric Code (NFPA

No. 70), Code for Motor Fuel Dispensing Facilities and Repair Garages (NFPA No. 30A) and

all national, state and local codes.

All wiring running to the system must be installed in threaded, rigid metal conduit and have the

required sealoffs. AC and DC power wires can share conduit, provided they meet the Petro-

Net™ wiring specified; otherwise AC and DC power wires must be installed in separate

conduits.

3.1.1 Conduit Sealing

Conduit entering the hazardous area must have a seal-off installed 18 inches (46 cm) above grade to prevent

liquid or fumes from entering the area.

When running shielded cable through a seal-off, strip the cable jacket back so about three (3) inches (7.6 cm)

of jacketed cable protrudes past each seal-off.

WARNING:

Shielded cable is NOT vapor-tight! DO NOT damage the shield

wire! Stripped section must be in the sealed-off area.

Doc. No.: M1900 Rev.: 8

Page 16 of 65

Содержание M1900

Страница 48: ...Program a Carded System Doc No M1900 Rev 8 Page 48 of 65...

Страница 56: ...Appendix A PV100 Primary Board PV100 Primary Board Doc No M1900 Rev 8 Page 56 of 65...

Страница 65: ......