4-2

Fiber Splicing Techniques

FiberPoint Structured Wiring Enclosure Installation Guide

Form 361015-0001A

have a tightly wrapped tip and be talcum-free. Pure optical

grade isopropyl alcohol is the recommended solvent for

cleaning connector tips. For removing dust from

receptacles, a canned compressed gas is recommended.

Cleaning Procedures

1.

Remove any accumulated dust or debris from the

connector by blowing off the cylindrical and end-face

surfaces of the connector using the compressed gas.

2.

Use a pad or a wipe saturated with optical-grade iso-

propyl alcohol to gently wipe the cylindrical and end-

face surfaces.

3.

Use compressed gas to blow dry the connector sur-

faces or allow them to air dry.

4.

Avoid touching the connector surfaces after cleaning.

If the connector is not going to be used, it should be

covered with a dust cap to prevent contamination.

H

ANDLING

OF

APC C

ONNECTORS

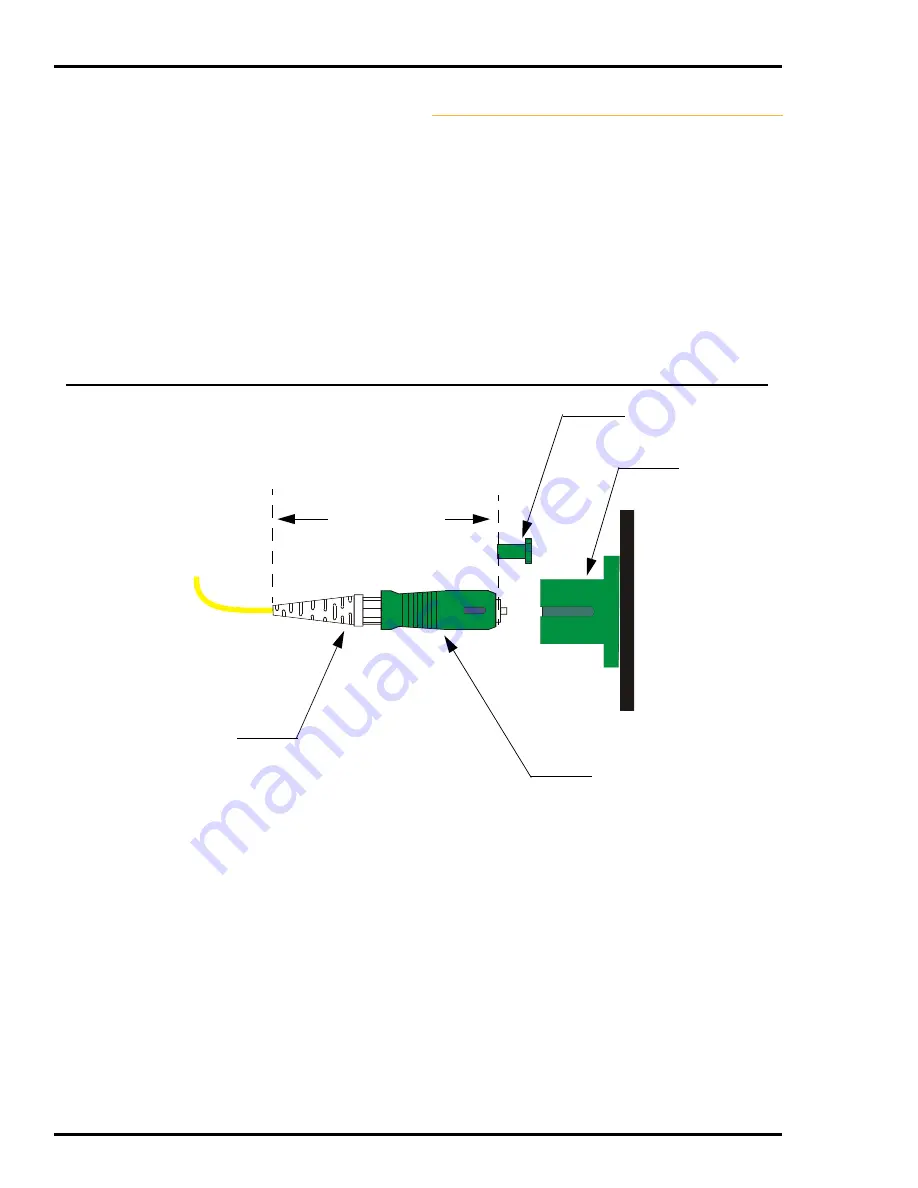

Although ruggedly constructed, fiber connectors need to be

handled with care when inserting the SC/APC connector

into the FiberPoint MEM. Follow these tips for making

secure, long lasting connections: (See ‘Figure 4-1: Fiber

Optic Connector Components’).

•

After removing the protective cap, make sure the fiber

end remains clean and moisture free.

•

Insert the connector into the bulkhead fitting by

grasping the rigid plastic fitting directly behind the fiber

output shroud. The connection is fully seated when

you hear it snap (“click”) into place.

•

Never attempt to insert the connector by gripping the

white or green flexible shroud. This may cause the

fiber to kink in the jacket, introducing unwanted noise

to the line.

Figure 4-1: Fiber Optic Connector Components

3008

Flexible Shroud. Do not

Grab Connector Here!

Rigid Plastic Fitting. Grab

Connector Here When

Inserting!

Remove Protective Cap

and Discard

Bulkhead Fitting

Proper Connector

must be less than

2.75” (6.99 cm)