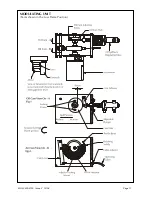

Modulating Control : Siemens RWF 40

Basic display

The diagram below shows the RWF40 after switching on the supply voltage. This conditions is called the

basic display. The actual valve and the currently active set-pint are shown here. Manual operation, self-

optimisation, the operating parameter and configuration levels can be activated from here.

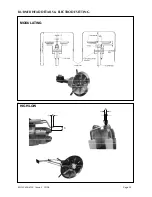

To change the working set point

The operating display shows the actual pressure/temperature of the boiler in red and the required set point

pressure/temperature beneath in smaller green digits. One quick press of the PGM button, the display

changes to show the set point as the larger red digits and the SPI in the lower small green digits.

Alter the red display using the up/down buttons to show the new required set point, press exit or let the

unit time out to return to the basic display which should be the new set point figure.

To enter a new parameter

The parameters dictate the way in which the burner firing rate alters in response to changes in the

pressure/temperature of the boiler.

A major factor that determines the need to change the parameters is if the burner is fitted to a steam or hot

water boiler. The table below indicates the parameter and its setting for steam and hot water boilers. It

must be emphasised that it is only an indication and any departure from these settings should be made in

small increments, with time given to see how the burner is reacting to the changed parameter.

Press and hold the PGM button down until the green set point figure changes to an AL, the larger upper

figures show the value. Use the up/down buttons to set the new values, press the PGM button to enter the

value and change to the next screen. To cancel an entry press exit. Scroll through the screens, (PGM

button) modifying any value found to be in error (up/down buttons). At the last screen the PGM button

will return the controller to the original display.

At any point in the procedure the original operating display can be obtained by letting the unit time out,

the value in the display at the time out will be accepted.

A value can only be altered within the permitted range of that parameter. All other parameters must

remain as supplied.

Note: The detector range parameters SCL & SCH are given as °C for Hot Water (temperature) and bar for

Steam (pressure).

MOL 3400-4100 Issue 2 10/08

Page 29

K6

PGM

EXIT

SIEMENS

Landis & Staefa RWF40

Burner enable

Reduce output

Increase output

Manual operation

Limit comparator

Increase value

Exit key

Process value display (red)

Setpoint display value (green)

Reduce value

PGM key

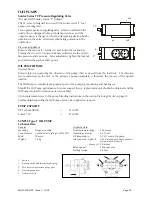

RWF Recommended Settings

Parameter Display

Hot

Water

Steam

Proportional

band

Pb1 10 1

Derivative time

Dt

10

5

Reset time

Rt

50

20

Actuator time

Tt

Set to the air Damper

running time between low

and high flame

Switch on

threshold

Hys 1

0

0

Upper off

threshold

Hyst 3

99.9

999.9

Detector:

range start

SCL 0 0

Detector:

range end

SCH 100 25