BURNER CONTROLS

Burners are supplied with an integral control panel containing a sequencing control unit and the burner

switchgear. On steam boiler applications an auxiliary control panel containing boiler feed pump controls,

water level interlocks and alarms is available.

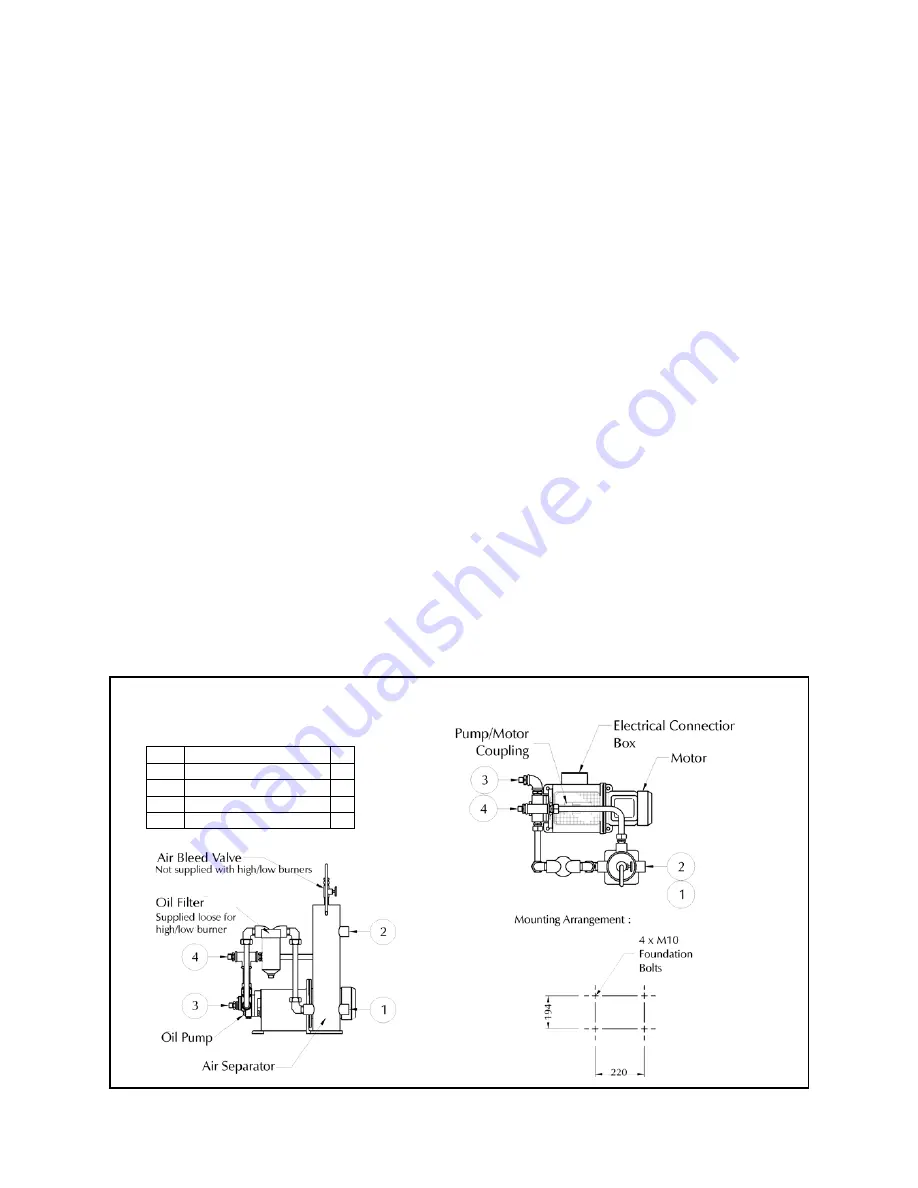

Oil Pumping Units

Standard burners are supplied with a floor-mounted pumping unit. Details of which are shown below.

On burners supplied in ‘compact’ configuration, the pumping equipment is mounted on the burner.

Modulating Unit

The modulating unit consists of a reversible servomotor, which is directly coupled to the camshaft of the

modulating unit. Two adjustable cams are mounted on this shaft, one of which is connected to a flexible

cable operating the burner air inlet control damper and is of the variable contour type (see fig 2 on page

17). The second cam is the modulating oil cam and is illustrated in fig. 1.

The

Burner Oil System

drawing on page 10 shows the hydraulic circuits. Oil for combustion is drawn from

the supply through a fixed displacement pump and supplied direct to the burner nozzle. A return line

from the back of the nozzle is connected to a ‘spill regulating valve’ which regulates the oil pressure at the

nozzle according to the position of an internal piston which is actuated by the oil control cam in the

modulating unit.

There is a well-defined relationship between the delivery of fuel through the nozzle and pressure behind

the nozzle, therefore movement of the oil cam ‘modulates’ the nozzle output and hence the output of the

burner.

The volume of air required for combustion must also be varied as the nozzle output varies, and this is done

by the air control damper, operated by a flexible steel cable connected to a lever system bearing against

the air control cam.

Once the oil has been adjusted as described in the

Commissioning

procedure section of this handbook, the

profile of the air cam is adjusted to give the desired combustion conditions by turning the thumbscrews

under the cam in or out as the burner is ‘inched’ through its firing range.

The air control damper is spring-loaded ‘open’ for safety in the event of cable failure.

MOL 3400-4100 Issue 2 10/08

Page 13

OIL PUMPING SET

Pipework Connections

Item Description R”

1 Oil Inlet Connection

1

2 Oil Return Connection

1

3 Burner Oil Feed

3/4

4 Burner Oil Return

3/4