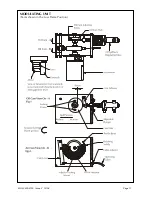

COMMISSIONING - HIGH/LOW BURNER

LOW FLAME

Switch on electricity supply. If controls are correctly set, burner fan will start, followed by oil pump,

providing air pressure switch changes over. Check rotation of each.

Air pressure switch is works set at 50mm wg, but may have to be adjusted to suit installation.

After pre-purge period has elapsed the low flame solenoid valve will open allowing oil to spray through the

low flame nozzle only and be ignited by the HT spark which is already present.

The photo-electric (PE) cell should take over and burner will run.

At this stage adjust the air regulator to give a visibly clean flame.

Do not fire the burner for long periods until warming up of appliance is completed. During warm-up

check lockout period by ‘blacking-out’ PE cell while burner is firing: burner should stop within one second.

Keep PE cell covered: after between 20 and 40 seconds burner should start its cycle again. It should lock

out five seconds after the low flame solenoid valve is energised. The air regulator should now be set to

give a CO

2

reading of 10-11% with a smoke number of 0-1.

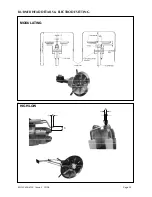

HIGH FLAME

When the appliance is ready to be fired at high flame, move switch on control panel to this position. The

two high flame solenoid valves will be energised. The normally closed valve will open and allow

pressurised oil to pass to the hydraulic cylinder actuating the air regulator. At the same time the other,

normally open, high flame solenoid valve will close to prevent oil reaching the high flame nozzles until the

air regulator has moved and actuated the sequencing microswitch. The micro switch controls this second

high flame valve and should be adjusted to give a clean changeover from low to high flame. (See page 9).

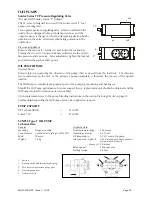

With the burner operating on high flame adjust the air regulator to give a CO

2

reading of 12-13% and a

smoke number of 0-1.

If silencer has been removed, refit and again check CO

2

and smoke readings, readjusting the air regulator if

necessary.

MOL 3400-4100 Issue 2 10/08

Page 19