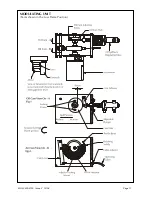

FLAME FAILURE & SEQUENCE CONTROL – Siemens LAL.1 Burner Control

The unit is designed to provide control and supervision for atomising oil burners of medium to large capacity. They

are suitable for use on multi-stage and modulating burners.

For safety reasons, at least one controlled shutdown must be provided within each 24-hour period of continuous

operation.

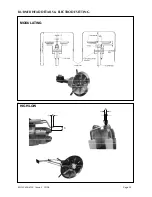

When a burner failure is encountered the box goes into lockout mode. This is indicated by an orange neon, which

displays within the lockout window of the control and is repeated at the lockout lamp on the panel facia.

If a lockout situation occurs, the burner will not start until it is manually reset by pressing the lockout window on the

control. (The control can also be reset by the off/on reset switch situated on the control panel facia).

If the burner fails to fire and persists in locking out,

no more than three attempts should be made

. To do so will

almost certainly create a

dangerous situation

.

If a burner becomes troublesome then the assistance of a qualified engineer should be obtained. To assist in his

diagnosis, notes should be made detailing the events leading up to the lockout situation. The symbol appearing in the

lockout window should also be noted prior to re-setting the burner.

(Refer to the Sequence Diagram and Timing Chart

below)

.

PLEASE NOTE:

When the control box goes to lockout it is generally performing the function it is designed for.

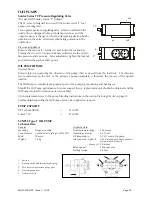

Burner Control Program

Burner operated sequence based on the Siemens LAL1.25 Control Box. Note: Timings are for operation on a 50Hz

electrical supply only.

MOL 3400-4100 Issue 2 10/08

Page 27

t6

Burner

Motor

Air

Damper

Ignition

Main Oil

Valves

Flame On

t2 t3

t4

t5

t7

t1 t8

Ts

Run Tp

T

Period

Time

(secs)

Description

t1

2.5

Start-up time for fan motor

t2

5

Start-up to ‘open’ signal

t3

54

Modulating servo to ‘High Flame’

t4

22.5

Full air pre-purge

t5

54

Modulating servo to ‘Low Flame’

t6 54

Pre-ignition

t7 5

Safety

period

t8

15

Release to RWF 40 Controller

Ts

155.5 Total start-up time

Tp

15

Post purge time

T

170.5 Control re-cycle time