4-8

Power-Up

and

Testing

4.7.2 Scale

Setup

1.

In the FmXP Main Window, select

Configuration > Setup Scale

.

!

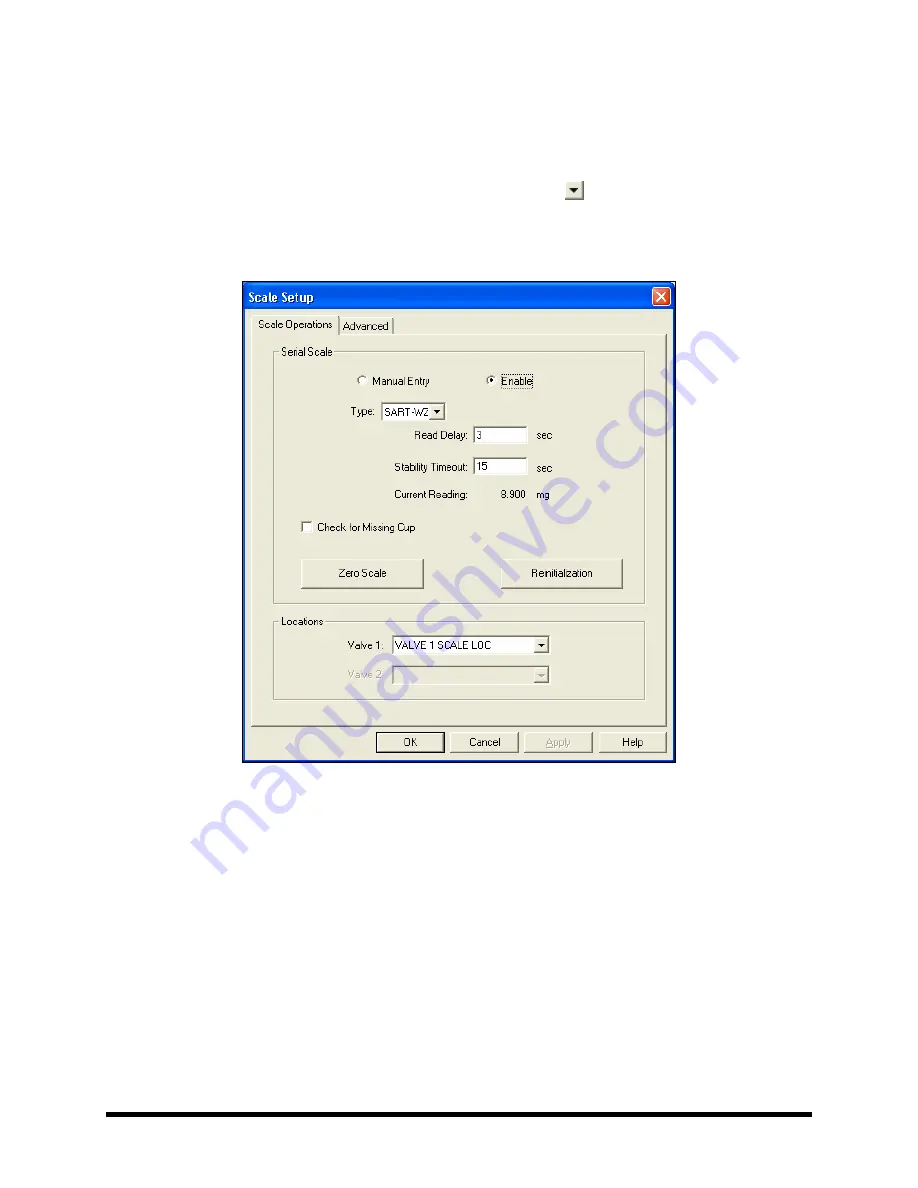

The Scale Setup window opens (Figure 4-7).

2.

Verify that Scale Type is SART-WZ. If not, click on the and select SART-WZ from the

drop-down list.

3.

Click on

OK

to exit the Scale Setup window.

Figure 4-7 FmXP Scale Setup

Содержание Asymtek Spectrum S-920

Страница 1: ...Spectrum Series S 920 Dispensing System Installation Operations Maintenance Manual P N 7212417 Rev A...

Страница 2: ......

Страница 4: ......

Страница 30: ...1 14 Introduction 1 10 5 Rear View Figure 1 7A Rear View 2 3 4 1 5...

Страница 124: ......

Страница 172: ...7 12 Maintenance Figure 7 7 Lubricating the X Axis Linear Guides Figure 7 8 Lubricating Y Axis Linear Guides...

Страница 185: ...Troubleshooting 8 11 Figure 8 3 FmXP Scale Setup Menu Figure 8 4 Scale Error Message...

Страница 190: ......

Страница 204: ......

Страница 208: ......

Страница 210: ......

Страница 220: ......

Страница 222: ......

Страница 223: ......

Страница 224: ......

Страница 225: ......

Страница 226: ......

Страница 234: ......