2205B0JE-DA-J-N_2014.05.

5 Maintenance and Inspection

Screw Compressor J-series

5.4 Disassembly and Assembly of the Compressor

5-23

5.4.6 Common Work Items

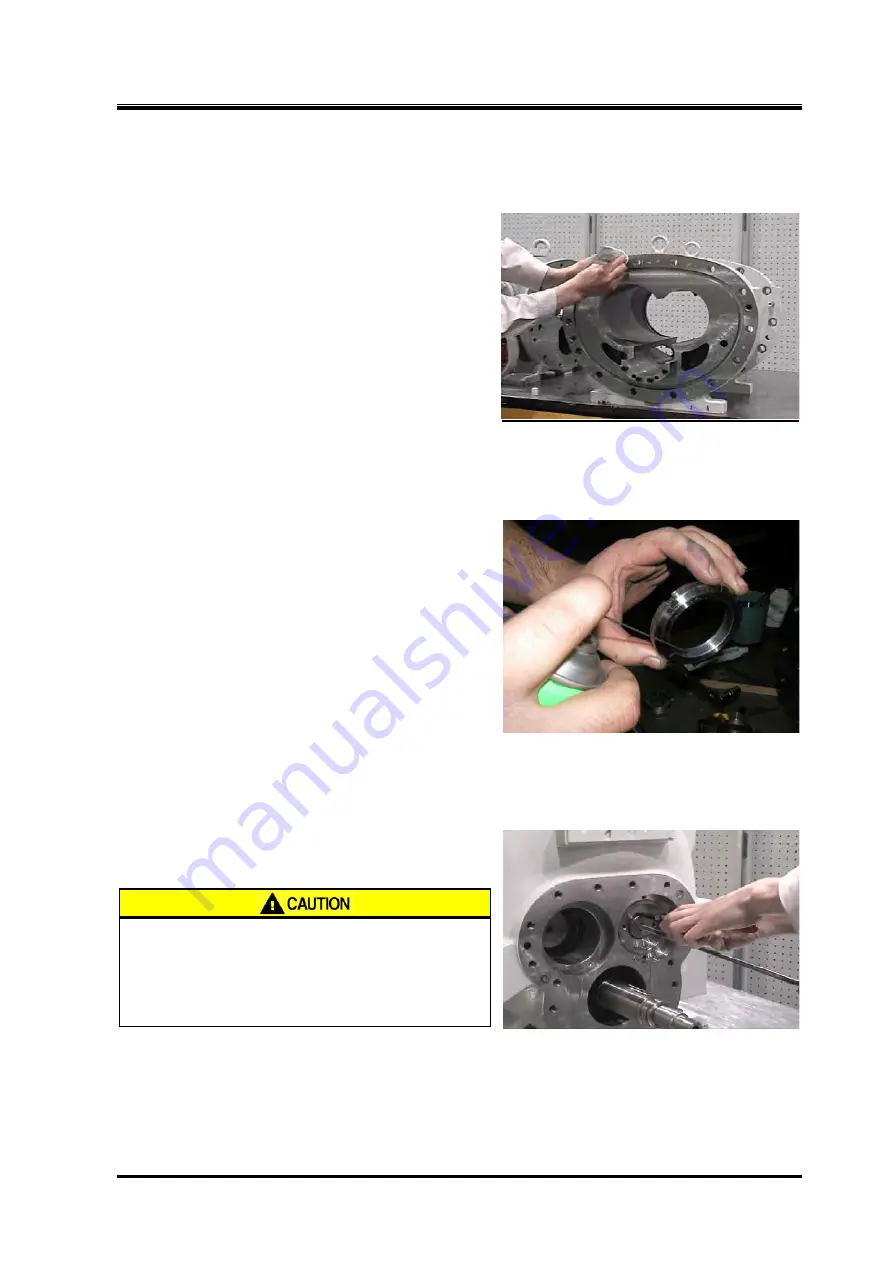

When attaching an O-ring, apply a thin coat of silicon grease to it.

When installing a casing or cover with an

O-ring, apply a thin coat of silicon grease to

the outer connecting faces of the O-ring

groove.

Clean the removed parts of any contamination and dirt. When storing the parts, take appropriate

measures to prevent rust and damage.

When assembling parts, make sure to lubricate them.

(bearing, balance piston, rotor)

For the parallel pin and locknut threads, apply

sticking-preventive lubricants. (molybdenum

disulfide, a solid lubricant).

Before hammering in the parallel pin, tighten the four bolts lightly in diagonal sequence with a

wrench.

Tighten the bolts, locknuts, and plugs, to the specified torque using a torque wrench. (Refer to

The Table for Tightening Torques of Bolts and Nuts.)

For the retaining ring, always use retaining ring

pliers that match the size of the stop ring.

When the size of the retaining ring pliers

is different, the retaining ring may jump

out, causing injuries. Always use

retaining ring pliers of appropriate size

and wear protective goggles.