2205B0JE-DA-J-N_2014.05.

5 Maintenance and Inspection

Screw Compressor J-series

5.2 Maintenance List

5-4

Daily maintenance items

1.

Lubrication oil level

When the oil level in the oil separator reaches the lower limit, charge lubricant by referring to the

instruction manual of the package/refrigerant system.

2.

Replacing Oil Filter

When the differential pressure between oil filter inlet and outlet is beyond pressure specified by the

manufacture, replace the oil filter element.

When starting operation, the oil filter differential pressure may increase in a short time.

In the case of differential pressure oil supply system, any oil supply differential

pressure (Discharge pressure – Oil supply pressure) exceeding over 0.15 MPa

may significantly decrease the thrust bearing life. Moreover, the oil filter element

may be broken, resulting in compressor damage.

3.

Cleaning Suction Strainer

When the compressor operating hours have exceeded 500 h, inspect the suction strainer and

remove the temporary filter for an initial period of operation if it is attached.

At the beginning of operation or just after the periodical maintenance, the differential pressure of

the suction strainer may increase in a short time. If the differential pressure increases, inspect and

clean the suction strainer.

4.

Oil Leak from Mechanical Seal

If there is a lot of oil leak from the mechanical seal, confirm the quantity of the leak per a hour.

The table below specifies the allowable leak rate and the upper limit for inspection.

If any damage is found in the mechanical seal during inspection, replace the mechanical seal.

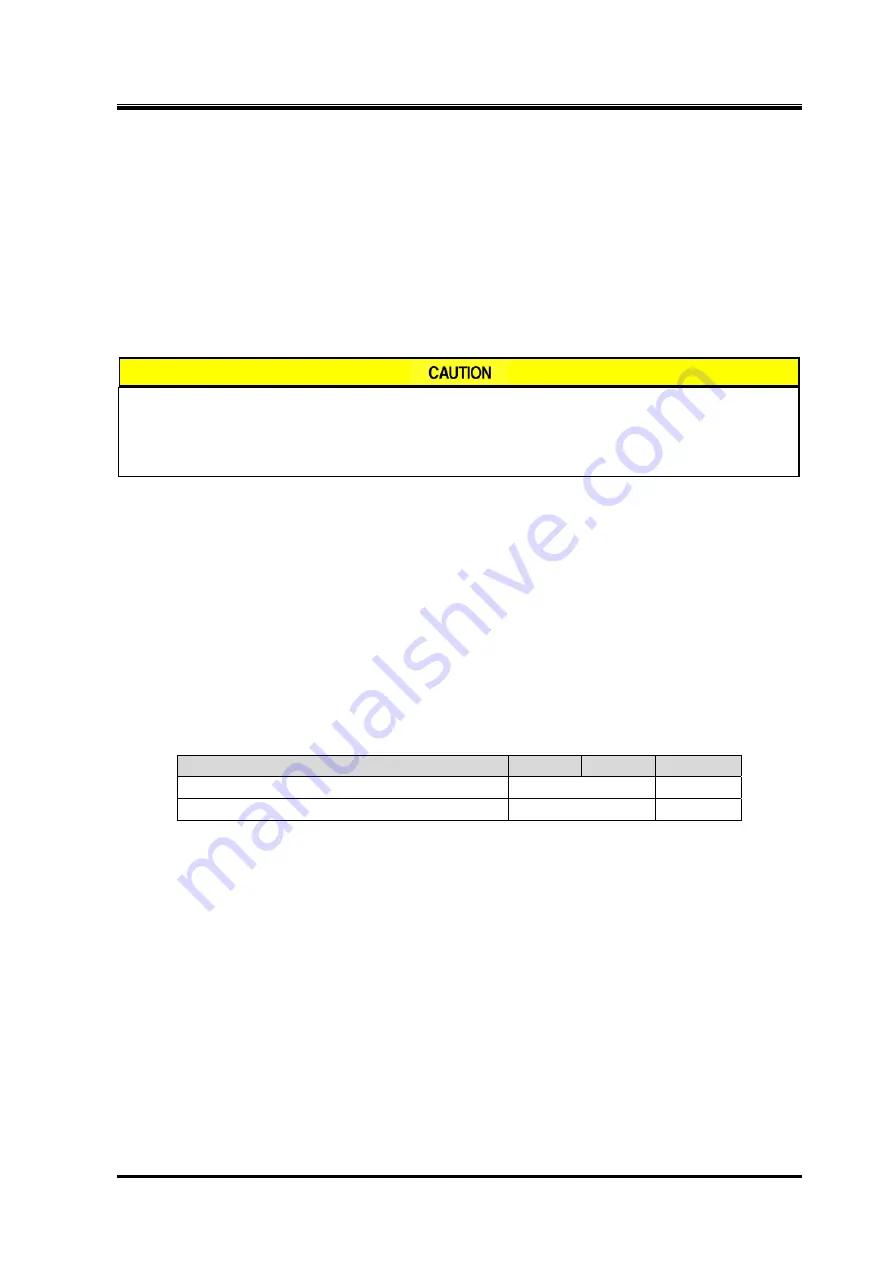

Table 5-2 Guideline for Leak Rate from Mechanical Seal

170J

220J

280J

Allowable leak rate (mL/h)

≤

3

≤

6

Rate at which inspection must be done (mL/h)

≥

9

≥

18

Note: The specifications above are just guidelines. They are not guaranteed value.

5.

Contamination of Condenser and Oil Cooler Pipes

The degree of clogging and contamination of the cooling pipes of the cooling water side is mostly

affected by the cooling water quality.

If the oil temperature and discharge pressure increase gradually in an initial period of operation,

inspect and clean the cooling water side of the oil cooler and condenser even when the inspection

time has not come.