2205B0JE-DA-J-N_2014.05.

3 Installation

Screw Compressor J-series

3.2 Installation Work

3-7

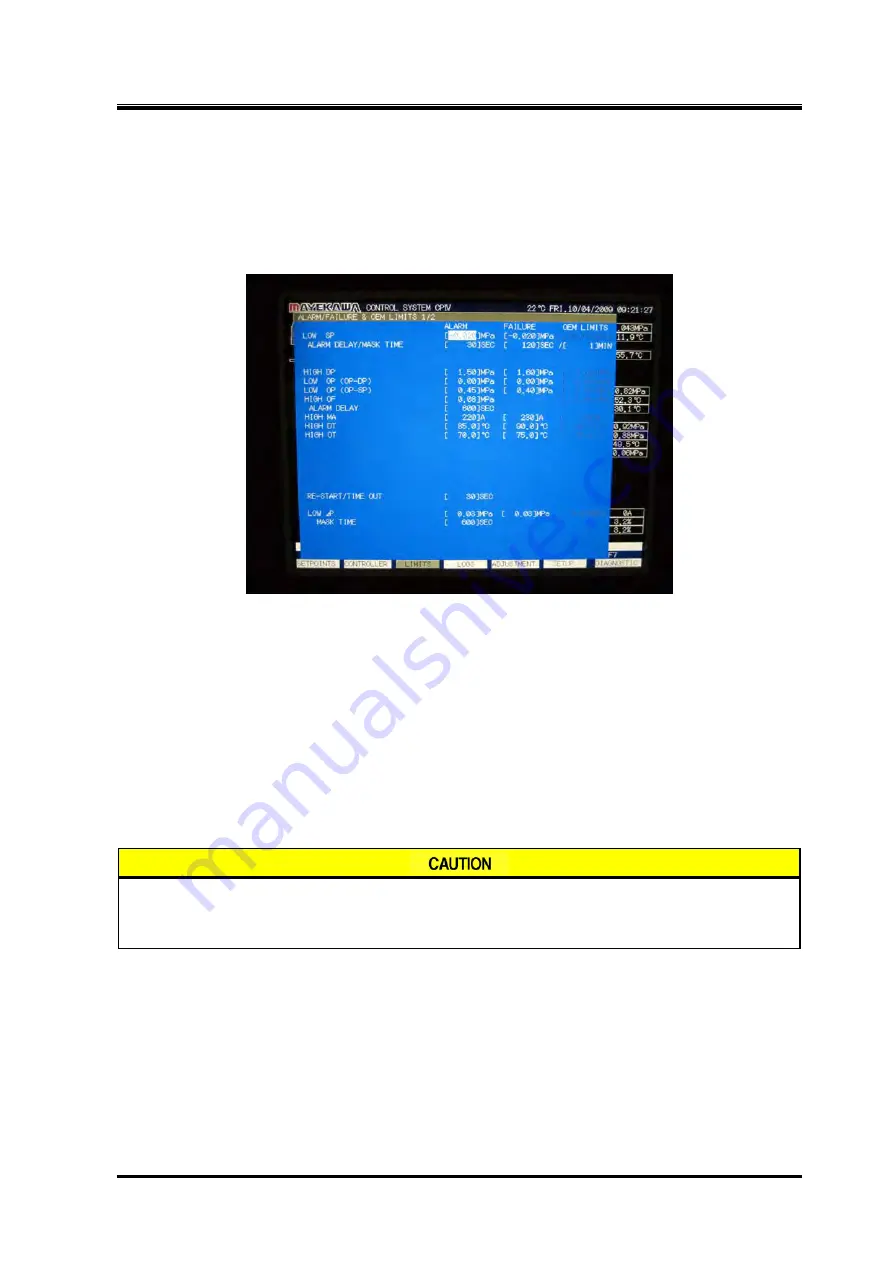

Lubrication temperature sensor (protection from abnormally high oil temperatures)

Discharge pressure sensor (protection from abnormally high discharge pressures)

Suction pressure sensor (protection from abnormally low suction pressures)

Oil pressure sensor (protection from abnormal oil pressures)

Motor input current ammeter (protection from motor overcurrent)

Figure 3-4 Controller Setting Screen (example)

Check the sensors and controller for proper protection function operation during test runs.

3.2.6 Pressure Test (Leak Test)

Perform pressure tests before starting operation. To prevent moisture entering in the package, use

nitrogen gas or dry air for the pressure test. Set the test pressure to the design pressure of the package

and maintain the pressure for at least 30 minutes while checking the flange connections and fittings for

any leaks using leak detector fluid (such as soapy water).

3.2.7 Lubricant (Refrigerant Oil) Charge

For the initial charge, always use new oil not exposed to air.

When adding lubricant, make sure that no air or water enters the package.

Store the lubricant in a sealed container placed indoors.

3.2.7.1 Initial Charge of Lubricant

At initial test operation or after periodical inspection, the compressor’s moving parts such as bearings

and seals may not have sufficient lubrication. Therefore, charge the compressor with lubricant

according to the following procedure.

1.

Thoroughly vacuum the compressor and oil separator to 40 Torr. Make sure that the unloader and

variable Vi solenoid valves are opened to vacuum the cylinders.

2.

Close the oil separator outlet valve in the oil supply line. Also close the oil injection regulating

valve.