2205B0JE-DA-J-N_2014.05.

5 Maintenance and Inspection

Screw Compressor J-series

5.4 Disassembly and Assembly of the Compressor

5-56

5.4.16.1 Precautions for Removal

Thrust bearing gland

1.

Protect the part of the male rotor where the mechanical seal is installed from being damaged by

using a curing tape.

Locknuts M and F / torsional slip washers / lock washers M and F

1.

Using a screwdriver, bend back the claw of

the lock washer.

Thrust bearing assembly for male rotor / thrust bearing assembly for female rotor

If the thrust bearings cannot be removed by hand, use the thrust bearing pulling tool. Take care

not to damage the inner and outer rings, balls and retainers of the thrust bearings.

5.4.16.2 Precautions for Installation

Thrust

bearing

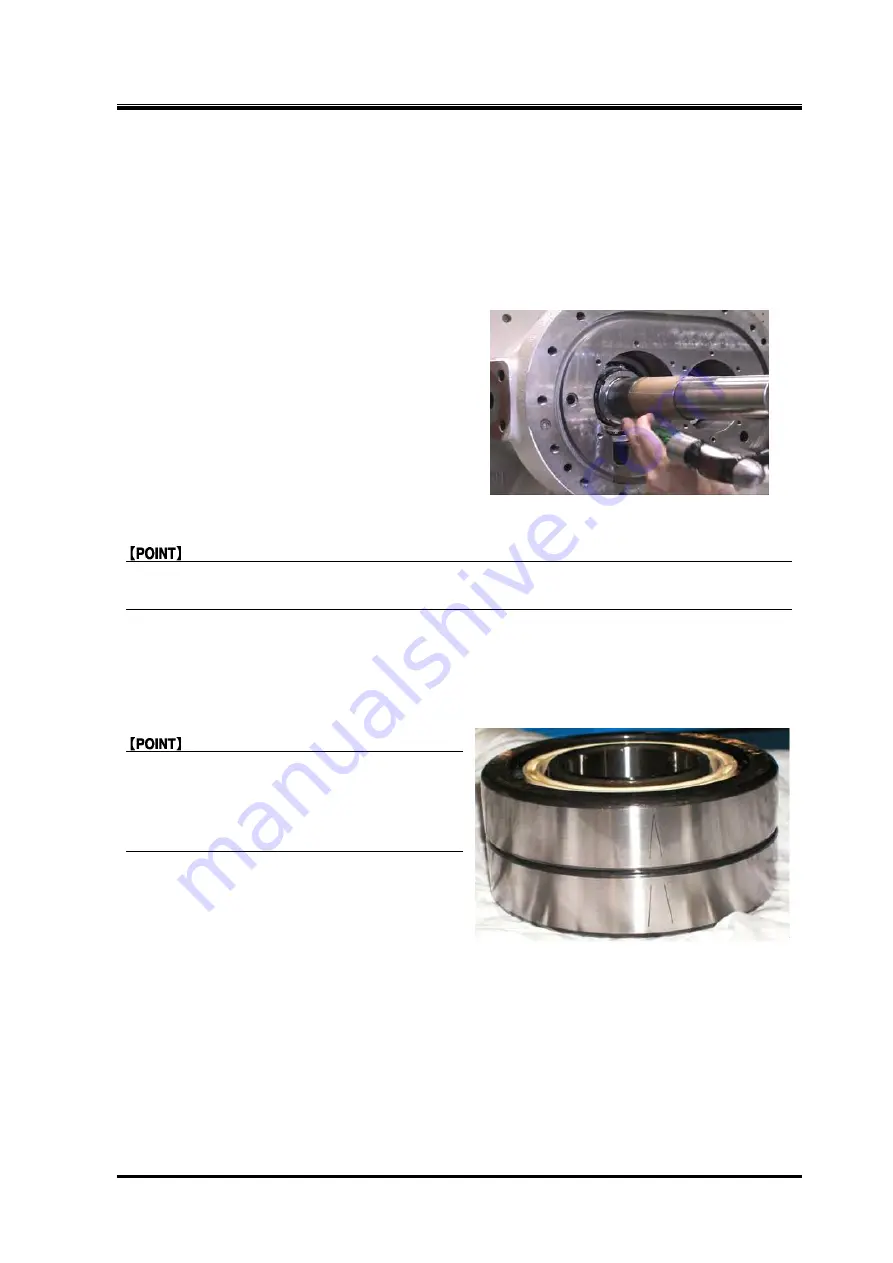

When replacing the thrust bearings, regarding

the direction of thrust bearing assembly, there

may or may not be a V-shaped mark for

assembly on the outer side of the bearing.

Follow the instructions below accordingly.

1.

If there is a V-shaped mark for assembly on

the outer side of the thrust bearing, assemble

with the pointed end of the mark on the inner

side of the machine due to a slight directional

difference that affects end clearance

adjustment.

If there is no V-shaped mark, assembly direction does not affect end clearance adjustment.

However, to clarify the difference between the inner side and outer side of the machine, after

assembling with the bearing number engravings on the outer side, make a V-shaped mark using

blue whetstone on the machine’s inner side of the bearing..