CWL-20E

|

9

|

en

Operation

8.

Operation

8.1

Preparing the work area

It is important that the surrounding area be properly

chosen and prepared before raising a load.

1.

Use the lift system only on hard surfaces capable of

safely supporting the load. The surface must be

strong enough to support the weight of the lift units

and the vehicle being raised. The ground pressure for

each lift unit (at maximum load) is 275 psi (19.3

kg/cm

2

).

The

ground

pressure

listed

is

an

approximation and may be higher under some

conditions. Hot asphalt can become soft and should

be avoided to prevent property damage or an unsafe

situation.

2.

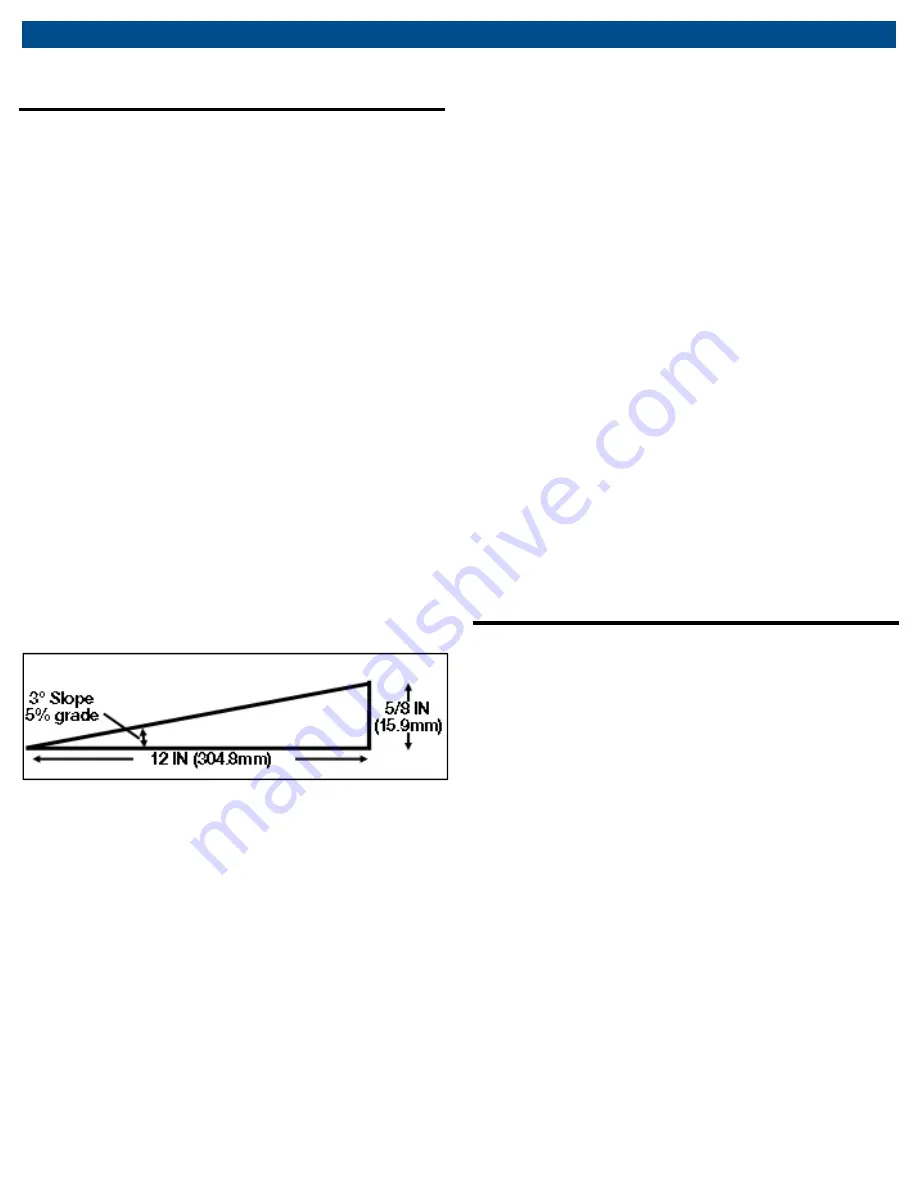

Use the lift system only on level, even surfaces. A

level surface is considered to be 3° slope or less. A

surface with 3° slope is equivalent to a 5% grade or

5/8 in. (15.9 mm) rise or drop per horizontal foot

(304.8 mm) (See Fig. 4 below. Note also that for each

degree of slope a surface rises or drops 0.210 in.

(5.33 mm) per horizontal foot (304.8 mm)). The surface

must also be free of ripples, ridges, depressions,

holes, or any undulation (e.g., a seam in a concrete

floor) that would cause only part of the lift unit’s

footprint to be in contact with the floor.

Fig. 4: Slope of ground under lift

3.

Make sure there is adequate clearance above the

highest point of the vehicle (including things like

vehicle exhaust pipes, air dams, etc.) so the vehicle

does not contact any overhead objects when raised

(e.g. ceiling/roof structural components, duct work,

hanging lights, heating/AC units, etc.). The lift system

can raise a vehicle as much as 24” (610 mm, but the

vehicle will extend vertically above this. The height of

the lift unit alone (at maximum lift height) is 77 1/4”

(1,962 mm).

4.

Clear the work area (especially the area underneath

the lift unit) of any unnecessary personnel, tools,

equipment and other materials. No unauthorized

personnel should be allowed in the work area where

the lifts are being used.

5.

If the lift system is used outdoors the operator

assumes all risk. Understanding that these are

portable lifts, it is foreseeable that they can and will be

used outdoors.

WARNING!

If lift units are used outdoors the following

conditions must be met:

Do NOT use lift units when wind speeds or gusts

exceed 20 mph to avoid tipping or loss of load.

Do NOT leave lift units unattended when used

outdoors to avoid inadvertent operation by untrained

operators and unforeseen changes in weather

conditions.

Do NOT use lift units outdoors when precipitation of

any type is falling or expected during the time the

units will be used. There is a risk of electric shock if lift

units are used while precipitation is falling.

Do NOT charge lift units while outdoors. Only charge

lift units while indoors to avoid risk of electric shock.

If these conditions cannot be met, move the vehicle

and lift units (separately) to an indoor area where the

lifting operation can be performed safely.

WARNING!

NEVER attempt to move or reposition a

lift unit when a vehicle is raised on the lift unit.

8.2

Prepare the vehicle

1.

The vehicle’s wheels (or rims; not the tires) should be

at least 19 inches in diameter or else they could fall

through the cradle of the lift table (for example, if the

tires deflate). For wheels 16 to 19 inches in diameter

refer to the “Optional adapters” section on page 25.

2.

Check that the tires on the vehicle are properly

inflated and are in road-worthy condition. Make sure

the weight on any single tire does not exceed the

rated capacity of its lift unit, as the total weight of the

vehicle may not be evenly distributed across all lifted

tires. Also, be sure to consider the weight carried by

unsupported axles (i.e. a set of 4 lift units used to

raise a vehicle with three axles).