CWL-20E

|

11

|

en

Operation

8.4

Lift system initialization

1.

Make sure the master on/off switch (see the

“Component identification” section on page 8) on each

lift unit and the Touch Screen Controller

is set to the

OFF

position. Turn the master on/off switch of the

Touch Screen Controller

to the

ON

position. The

Touch Screen Controller will initialize and then the

screen shown below will appear on the touch screen.

(NOTE: All screens shown in this manual are

simplified versions of what is actually shown on the

display to help clarify button locations and functions.)

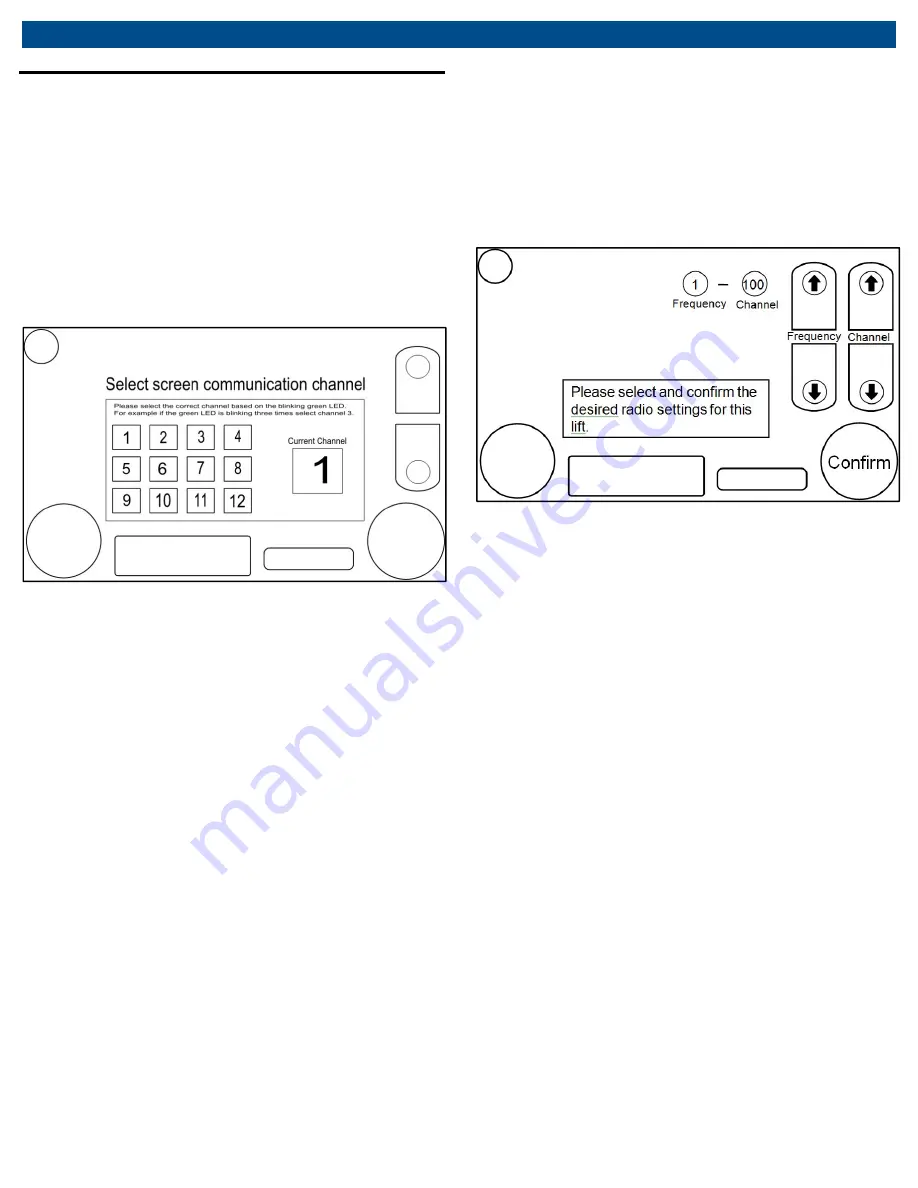

Fig. 6: Selecting screen communication channel

2.

Select the desired Touch Screen Controller radio

frequency. The most recently used frequency will

already be set. If the most recently used frequency is

acceptable, a frequency does not need to be chosen

and accepted. To choose a new frequency, push the

icon corresponding to the frequency desired. All units

that will be used together as a lift system to lift a

vehicle must be set to the same frequency as the

Touch Screen Controller. There are 12 radio

frequencies available for use. Refer to Section 11

“Using multiple lifts in the same work area” for more

information on selecting the radio settings. When the

desired radio frequency is shown, push the

ACCEPT

button to advance to the next screen.

3.

Turn the master on/off switch of any lift unit to the

ON

position and then push the Communication Button

(see the “Component identification” section on page

8). If the touch screen frequency was changed on the

Touch Screen Controller then the touch screen

frequency will need to be changed on the lift to match

that of the Touch Screen Controller. The lift unit’s

touch screen frequency will be indicated by the blink

pattern shown with the Status Indicators on top of the

Electronics

Enclosure

(see

the

“Component

identification” section on page 8). The number of

successive flashes between breaks will be the touch

screen frequency that is set on the lift unit. If changing

the touch screen frequency on the lift, see section

8.13. If the touch screen frequencies of the lift and the

Touch Screen Controller match, then the screen

shown below will appear on the touch screen. If

nothing happens, the frequencies do not match and

will need to be reset so that they do.

Fig. 7: Select radio settings for lift

4.

Select the desired radio settings. The default radio

settings will be the settings selected the last time the

unit was used. Push the up and down arrows on the

right side of the screen to change the radio frequency

and/or channel, if needed. All units that will be used

together as a lift system to lift a vehicle must be set to

the same frequency and channel. There are 12 radio

frequencies available for use and the channel can

range from 100-120 for each frequency. Refer to

Section 11 “Using multiple lifts in the same work area”

for more information on selecting the radio settings.

When the desired radio settings are shown, push the

CONFIRM

button to advance to the next screen.

5.

Read through the Notice that is displayed on the next

screen. If the operator agrees with and acknowledges

the statements made on the screen, push the

ACCEPT

button to continue setting up the lift system.

6.

The display then changes to ask how many lift units

will be part of the lift system. Push the button that

corresponds with the total number of lift units that will

be used in the current lifting system.

7.

The display will now appear as shown below with a

picture of a vehicle asking for the current lift unit’s

position relative to the vehicle. Select the round button

with a number inside it that matches the current lift unit’s

position. Once the position is selected the position button

will turn green to indicate the selection.