Torchmate 4000 Series

30

Cut Quality

Line Speed Test:

Line Speed Test Cut:

The total goal is to make sure the cuts coming off of your table are the best possible. This means

that there is minimal dross accumulation on the underside of your cut parts and minimal bevel

on the sides.

We have provided a file to cut to verify the feed rate for the material you are planning to cut with

the amperage set on the power supply. The LINE SPEED TEST is in the job list and should be run

on every thickness of material at the specified amperages in the cut chart to give you a visual

reference to the output. The test cut is a 3" x 4" coupon that consists of nine lines. Each line is

programmed to run at different speeds to illustrate the effects that speed has on cut quality.

With the FEED RATE OVERRIDE % at 100, the first line cuts at 170 ipm and drops 10 ipm each

line until the last line set at 80 ipm, and the outside perimeter is 100 ipm. If the FEED RATE

OVERRIDE % set to 50, the lines would range from 85 to 40 with the outside at 50. In the cut

chart, verify the amperage and thickness of the material. Change the PROGRAM FEEDRATE

OVERRIDE % if you need the feed rates higher or lower according to the thickness of the

material and amperage you are running.

Load the LINE SPEED TEST.gm file

Enter in the AVHC settings according to the cut chart.

Jog the head to the bottom left corner. SET PLATE ORIGIN.

Run the LINE SPEED TEST.

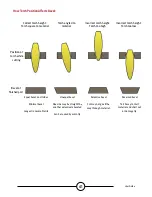

Once the test is complete there are a few things to look for. On the top of the cut you want to

see a clean cut without a lot of bevel. Ideally, it has the same kerf width both on top, all the way

through to the bottom.

On the backside you will observe the width of the cut and the dross accumulation. The key is the

3-4 lines that have least amount of dross. The dross should be easy to remove by picking at it.

Usually the optimum speed is the high end of the three lines that are relatively clean. Straight

lines will cut relatively clean but the "inside features" of your cuts will be at a lower speed

because of the nature of movement and mechanics of the machine. With those three you know

that the inside features will be just as clean as the straight line.

So in this example the 110 - 90 ipm will be the best speed for this material thickness and

amperage setting. Now this process will be used for every thickness of material you plan on

cutting to establish the proper speed. Once established, these coupons can be used as a visual

cut chart or you can use the provided sheet to document your settings.

Содержание LECS-080-4400-00

Страница 1: ...USERGUIDE October 12 2021 Copyright 2021 Lincoln Electric Cutting Systems TORCHMATE 4400 4800 4510 ...

Страница 2: ......

Страница 55: ......