Maintenance Procedures cont'd

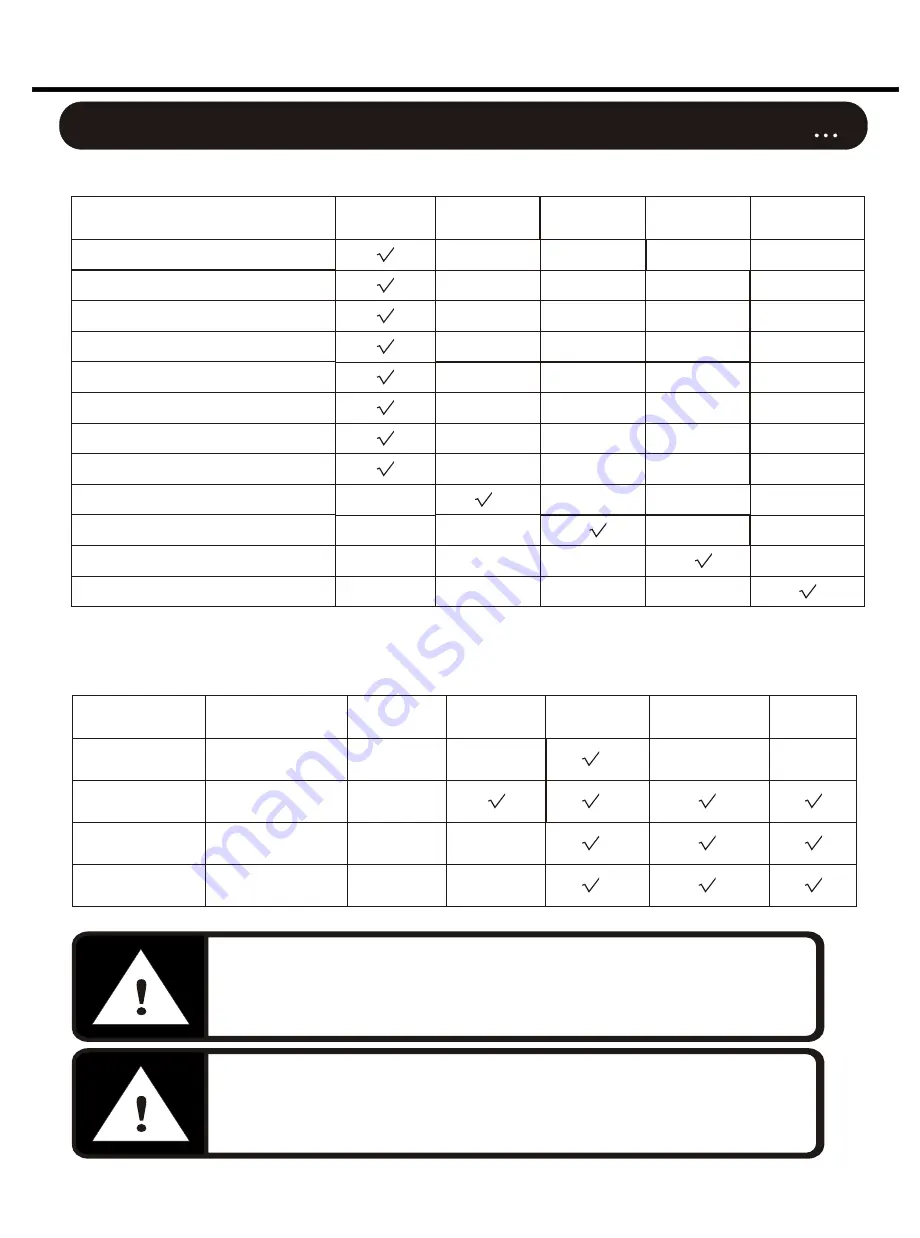

2. Maintenance Schedule

Item to check

10 Service

Hours

15 Service

Hours

25 Service

Hours

50 Service

Hours

Every Six

Months

Operator Presence System

Brake Adjustment

Teeth and Cutter Wheel Assembly

Tires and Chip Curtains

Walk Around Inspection

Wires and Cables

Bolts and Mounting Hardware

Safety Labels

New Drive Belt

Grease Cutter Shaft Bearings

Drive Belt Tension

Wheel Bearings

3. Lubrication Schedule

Regularly scheduled lubrication of the LGSG13HC is essential to smooth performance and extended equipment

life. The following schedule is a recommended guide to lubricating your LGSG13HC. The schedule should

be adjusted for various environmental conditions and frequency of use.

Item

Suggested

lubricant

Every 20

hours

Every 60

hours

As required

After each

pressure wash

storage

Engine

Refer to owner's

manual for Engine

Wheel

Lithium-based

Grease

Cutting Teeth,

Pockets & Wheel

General purpose

spray lubricant

Zerks

General purpose

spray lubricant

Technician should read and thoroughly understand all manuals pertaining

to the machine to be serviced. Do NOT proceed with any service and

maintenance activity until ALL questions and concerns have been addressed.

Please call your local dealer for technical support andadvice.

! ALWAYS consult and verify that all local codes and bylaws are followed

before performing any service or maintenance procedures.

18

Содержание LGSG13HC

Страница 1: ...original instruction 2013 LGSG13HC Uniguip...

Страница 7: ...Machine Parts Breakdown 5 LGSG13HC...

Страница 8: ...Machine Parts Breakdown 6 LGSG13HC...

Страница 9: ...Parts List 7...

Страница 10: ...Parts List 8...

Страница 11: ...Parts List 9...

Страница 13: ...Machine Overview cont d 11...

Страница 27: ...Notes 25...