Maintenance Procedures cont'd ..

4. Sharpening cutter teeth

Sharpening stump grinder teeth produces dust that is hazardous to people

and animals. Do not sharpen teeth in the absence of a dust collection system

and adequate ventilation. Cutting tools may shatter if they are misused. Be

sure to use shields and eye protection when sharpening or in the vicinity of

sharpening.

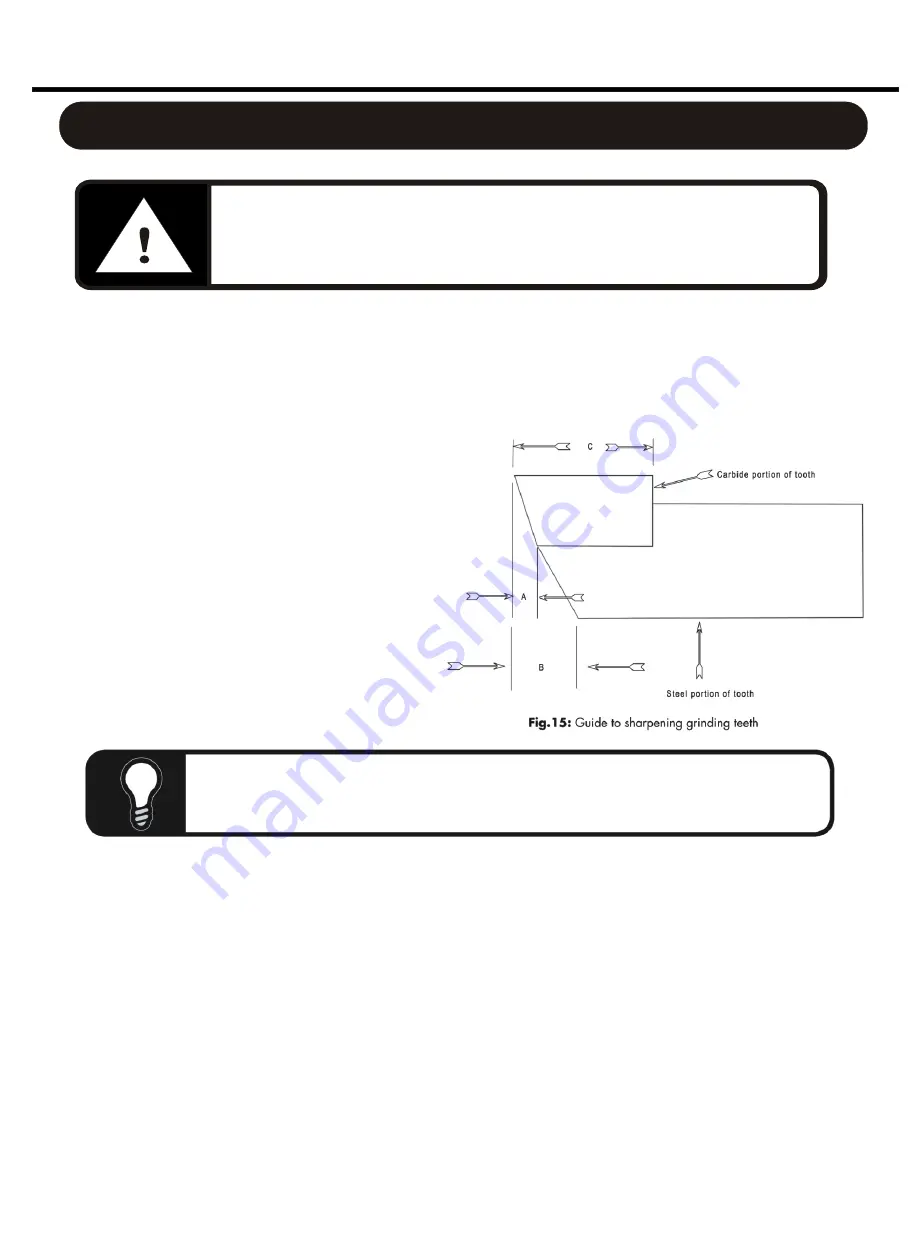

Stump grinder teeth have a carbide tip that is silver soldered to a steel base. The carbide tip is what actually cuts

the stump. The tip also shields the steel beneath it from being worn away. Maintaining the sharpness of the carbide

and keeping down relief at10 degrees (see Dimension A, Figure 15) will result in a machine that cutsmore efficiently

than a machine that has dull teeth.

To sharpen the tooth properly, you must use two different wheels one wheel for the carbide and another for

the steel. The procedure for sharpening teeth is as follows:

i. Use the steel grinding wheel to grind

away some of the steel that is beneath

the carbide tip. Grind steel at a

12 degree angle (see Dimension B,

Figure 15)

ii. Use the carbide wheel to grind the

carbide at a 10 degree angle

(see Dimension A, Figure 15).

Grind until the carbide does not overlap

with the steel and the top edge of the

carbide is sharp.

iii. Teeth may be sharpened as long as

3/8 of carbide remains on the tip

(see Dimension C, Figure 15).

Replace any tooth that has less than

3/8 of carbide left.

Do not attempt to cool stump grinder tooth after grinding by immersing it in

water. Immersing hot tooth in water may cause carbide to crack.

22

Содержание LGSG13HC

Страница 1: ...original instruction 2013 LGSG13HC Uniguip...

Страница 7: ...Machine Parts Breakdown 5 LGSG13HC...

Страница 8: ...Machine Parts Breakdown 6 LGSG13HC...

Страница 9: ...Parts List 7...

Страница 10: ...Parts List 8...

Страница 11: ...Parts List 9...

Страница 13: ...Machine Overview cont d 11...

Страница 27: ...Notes 25...