Changing the oil filter

1. WARNING!

Compressed air!

Compressed air and devices under pressure can injure or cause death if the contained energy

is released suddenly.

➤ De-pressurise all pressurised components and enclosures.

2. Unscrew the oil filter anti-clockwise, catch oil spillage and dispose of in accordance with envi‐

ronmental protection regulations.

3. Lightly oil the new filter's gasket.

4. Turn the oil filter clockwise by hand to tighten.

➤ Dispose of parts and materials contaminated with oil in accordance with environmental

protection regulations.

Starting the machine and carrying out a trial run

1. Close all access doors, replace and secure all removable panels.

2. Open the user's shut-off valve between the machine and the air distribution network.

3. Switch on the power supply and reset the maintenance interval counter.

4. After approx. 10 minutes of operation: Check the cooling oil level and top up if necessary.

5. Switch off the machine and check visually for leaks.

10.18 Changing the oil separator cartridge

The oil separator cartridge cannot be cleaned.

The life of the oil separator cartridge is influenced by:

■ contamination in the air drawn into the compressor,

■ Adherence to the changing intervals for:

─ Cooling oil

─ Oil filter

─ Air filter

The machine must be isolated from the compressed air network and completely vented be‐

fore undertaking any work on the pressure system.

Material Spares

Cleaning cloth

Precondition The supply disconnecting device is switched off.

The disconnecting device is locked in the off position.

A check has been made that no voltage is present.

The machine is fully vented,

the pressure gauge on the oil separator tank reads 0 bar.

10 Maintenance

10.18 Changing the oil separator cartridge

80

Operating Manual Screw Compressor

ASK

901824 12 E

Содержание ASK 28

Страница 2: ...Original instructions KKW SASK 2 22 en SBA SCHRAUBEN SC2IO KKW SSC 2 08 20170919 084918...

Страница 6: ...Contents iv Operating Manual Screw Compressor ASK 901824 12 E...

Страница 8: ...List of Illustrations vi Operating Manual Screw Compressor ASK 901824 12 E...

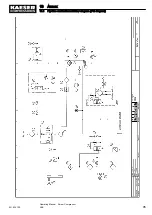

Страница 104: ...13 Annex 13 1 Pipeline and instrument flow diagram P I diagram 94 Operating Manual Screw Compressor ASK 901824 12 E...

Страница 105: ...13 Annex 13 1 Pipeline and instrument flow diagram P I diagram 901824 12 E Operating Manual Screw Compressor ASK 95...

Страница 106: ...13 Annex 13 1 Pipeline and instrument flow diagram P I diagram 96 Operating Manual Screw Compressor ASK 901824 12 E...

Страница 107: ...13 Annex 13 1 Pipeline and instrument flow diagram P I diagram 901824 12 E Operating Manual Screw Compressor ASK 97...

Страница 108: ...13 Annex 13 1 Pipeline and instrument flow diagram P I diagram 98 Operating Manual Screw Compressor ASK 901824 12 E...

Страница 115: ...13 3 Dimensional drawing 13 Annex 13 3 Dimensional drawing 901824 12 E Operating Manual Screw Compressor ASK 105...

Страница 118: ...13 4 Electrical Diagram 13 Annex 13 4 Electrical Diagram 108 Operating Manual Screw Compressor ASK 901824 12 E...

Страница 138: ...13 Annex 13 4 Electrical Diagram 128 Operating Manual Screw Compressor ASK 901824 12 E...