For the ACX500 outdoor routers, perform the following additional steps as rust-preventative and

corrosion-preventative measure:

a. Clean both the mating surfaces (the grounding cable lug and the ACX500 outdoor router

grounding terminals).

b. Apply a thin film (0.04 in. or 1 mm) of corrosion-preventing compound, such as NO-OX-ID, on the

ACX500 outdoor router’s grounding terminals.

c. Press the lug onto the conductive surface unit in order to force out the excess corrosion-

preventing compound.

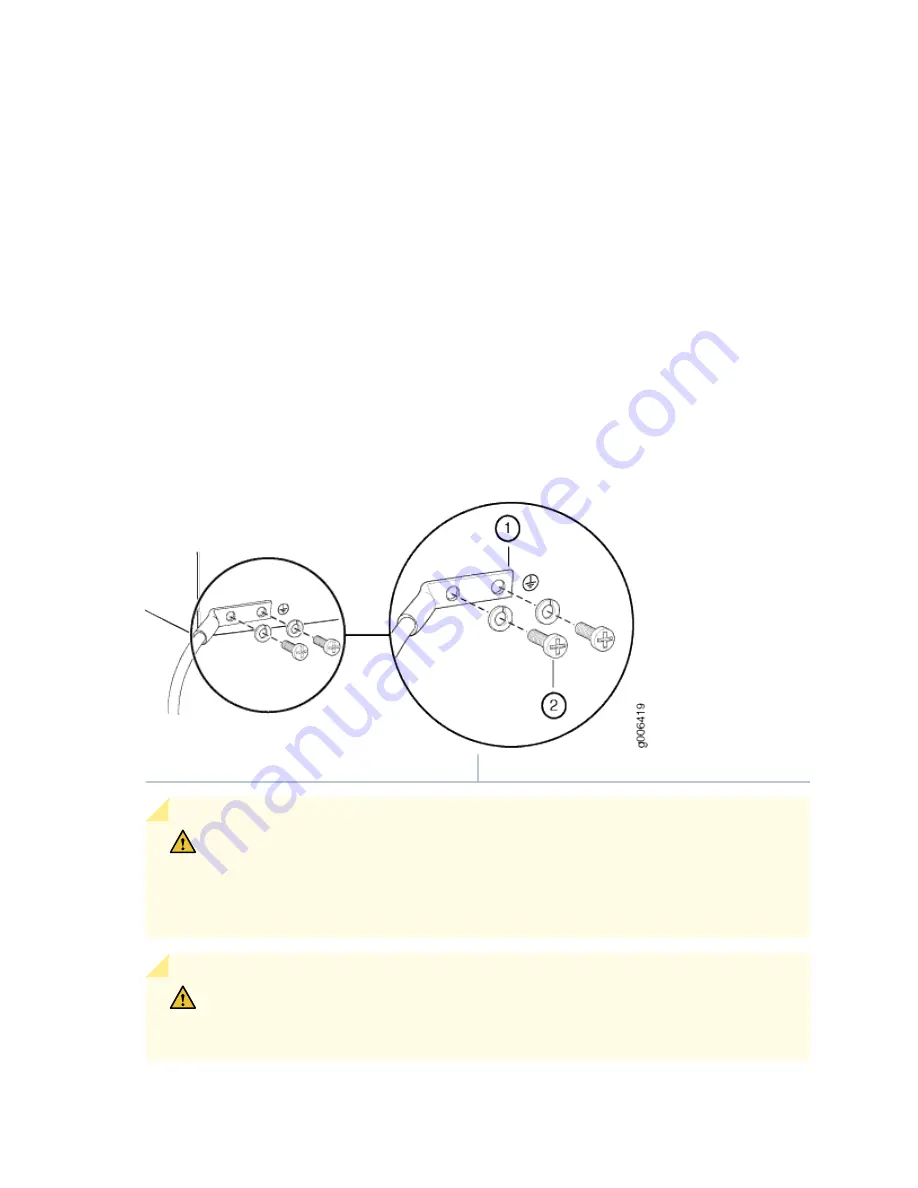

8. Secure the grounding cable lug with the washers and screws. The holes are sized for SAE 10-32

screws. Apply 4 lb-in. (0.49 Nm) of torque to each screw. Do not overtighten the screw (use a

number 2 Phillips screwdriver). See

Figure 56: Grounding Points on the ACX500 Indoor Router

1

—

Grounding lug

2

—

SAE 10-32 screws and washers

CAUTION: Ensure that each grounding lug sits flush against the surface of the

grounding points as you are tightening the screws. Ensure that each screw is properly

threaded into the grounding points. Applying installation torque to the screw when

improperly threaded can damage the terminal.

CAUTION: The maximum torque rating of the grounding screws on the router is 4 lb-

in. (0.49 Nm). The grounding screws can be damaged if excessive torque is applied. Use

only a torque-controlled driver to tighten screws. Use an appropriately sized driver,

160