Art. No. DS 4092 TS

basically the same.

If the actuator does not have a separate feedback function, the object "Value" and "Feedback

value" must be linked on the rotary knob to the objects via an identical group address.

Otherwise, no value adjustment is possible.

i

The actuator must actively transmit the feedback value on change.

i

After a device reset (bus voltage return or ETS programming operation), the value of the

communication object "Feedback value" is set to "0". A value adjustment then begins with

this value if the activated actuator has still not transmitted any feedback to the device with

an initialisation value that varies from this.

The effective step width for the value adjustment is obtained from the speed of a rotary knob

operation. During a slow operation (notch by notch), the rotary knob constantly transmits values

in small step width to the actuator. The value adjustment always begins with the value stored in

the communication object "Feedback value". During a slow, continuous operation, the value is

adjusted with each notch by the step width (1...31) configured in the ETS and transmitted via the

object "value". An activated dimmer actuator e.g. receives the value sequence dimming and

controls the brightness of the connected lighting system each time a new telegram is

transmitted, i.e. by one notch slightly brighter or slightly darker during each adjustment of the

rotary knob.

In contrast to this, a fast operation causes a significant change in brightness in this example by

the rotary knob transmitting a value with a greater step width to the actuator. The size of the

step width is determined by the rotation angle by which the rotary knob is turned within the

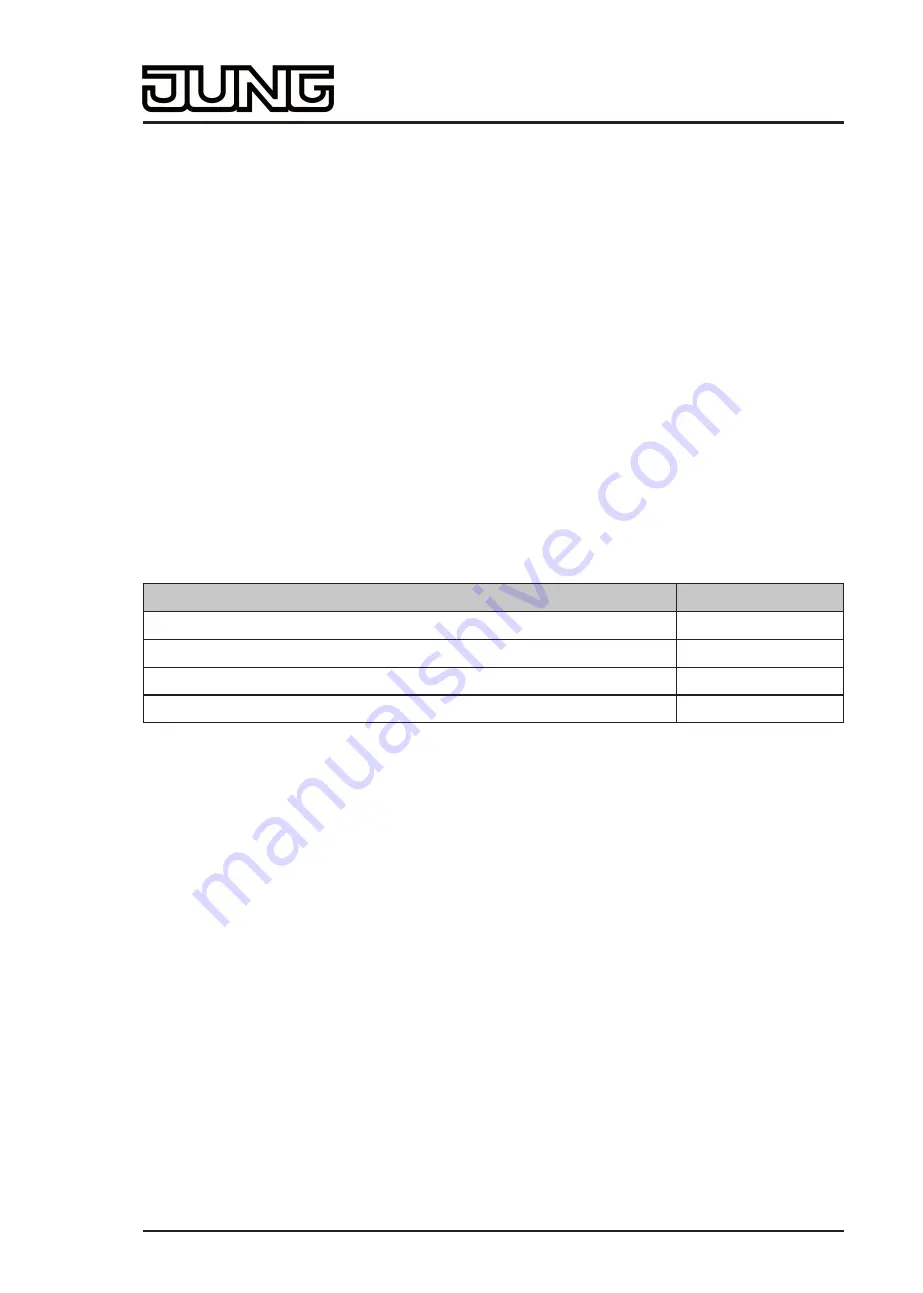

operation time. The table below shows the adjustment step widths depending on the rotation

angle during a fast rotary knob operation...

Rotation angle (rotation in segment)

Step width

45° (1/8 rotation)

31

90° (1/4 rotation)

63

180° (1/2 rotation)

127

360° (1/1 rotation)

255

Step widths depending on the rotation angle during a fast rotary knob operation

The rotation angle is interpreted by segments. Regardless of where the rotary knob operation

starts, a value corresponding to the step width is transmitted to the bus depending on the

segments during an operation (figure 26). At the end of the control operation, only one value is

ever transmitted if a corresponding segment was set. The device transmits no continuous value

sequence to the bus during a fast operation.

i

If the direction of rotation changes without interruption during an operation, the device

transmits a value corresponding to the adjusted rotation angle until the direction is

changed. Afterwards, no more telegrams are transmitted continuously until the rotary knob

stops. The device then evaluates this operation as a wrong operation.

Page 63 of 143

Software "Rotary sensor with extensions 10FE1x"

Functional description