incorporates special features to induce flow into the pump suction and to remove air that is present in

stock at higher consistencies.

2.3 Design concept

There are two major obstacles in pumping paper stock at consistencies above 8% with a centrifugal

pump: the formation of a fiber network that will not readily flow, and high air content which can cause air

binding of a standard centrifugal pump.

The Model 3500XD pump is normally attached to a suction vessel or "standpipe," and a constant level is

maintained above the suction centerline. An X-Ducer mounted on the end of the pump shaft creates tur-

bulence in the suction standpipe (Fig. 5, Zone 1), breaking up the fiber network and separating air from

the pulp. The pulp is then induced to flow into the pump suction by the static head in the standpipe and

the pumping action of the X-Ducer. The amount of turbulence required (minimum pump speed) as well

as the minimum standpipe level is a function of the stock type, quality, consistency and temperature of

each specific application.

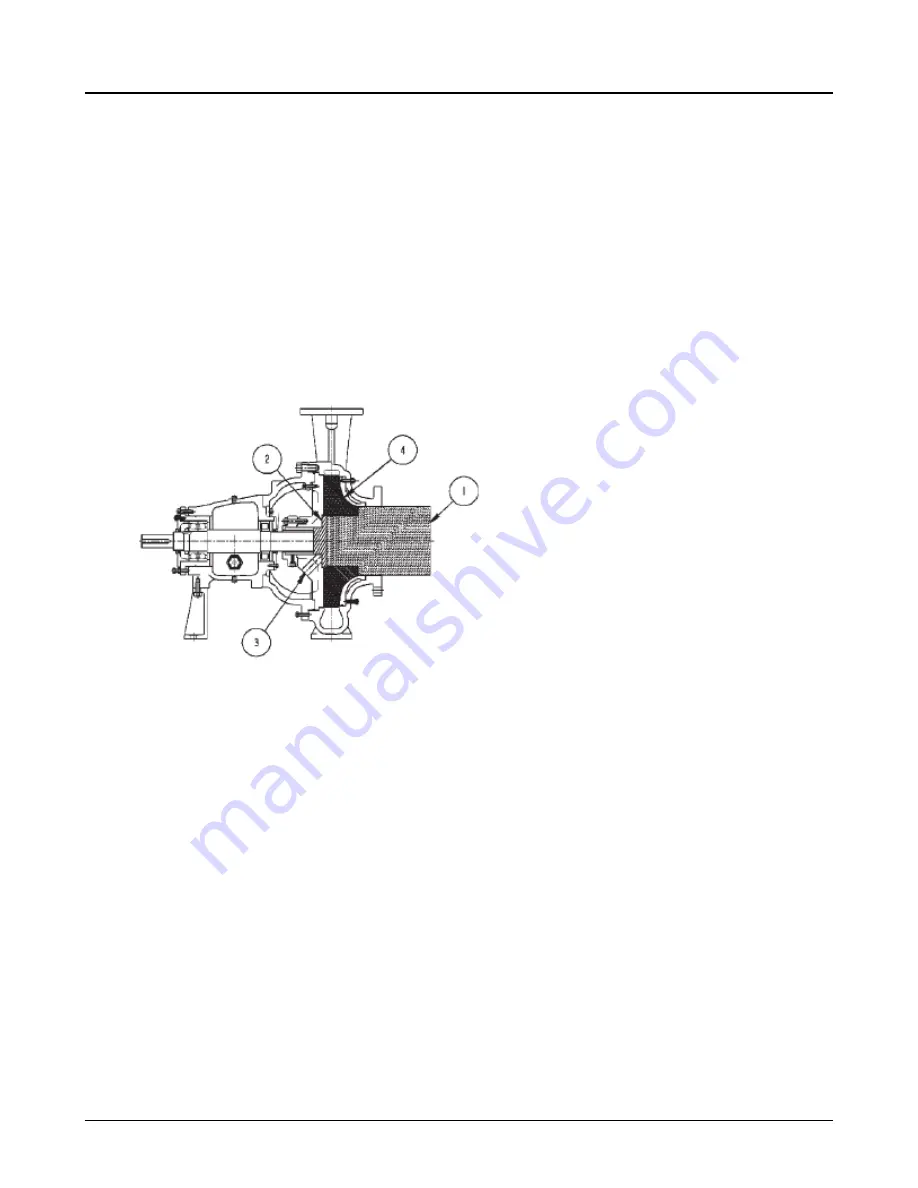

1.

Zone 1 - turbulence generation and air separation

2.

Zone 2 - Fiber return

3.

Zone 3 - Air removal

4.

Zone 4 - Pumping zone

Figure 5: Suction standpipe

Air separation occurs due to the action of X-Ducer in Zone

1.

The air collects at the center of the X-Ducer and is pumped through balance holes in the impeller

shroud. Any remaining paper stock is separated from the air behind the impeller via a patented

secondary separation device (U.S. Patent #5,087,171) in Zone 2. The paper

stock is pumped to the casing volute via large back pump-out vanes (Zone 4), and the air flows to

atmosphere or to a vacuum source depending on operating conditions (Zone 3).

Pressure generation takes place in the impeller and casing volute in the normal manner once the

air has been removed (Zone 4).

2.4 Construction details

Casing

- The casing is vertically split, top centerline discharge, providing a back pullout design for ease

of maintenance. A renewable sideplate is incorporated into the design to reduce maintenance costs. The

sideplate is sealed with an O-ring and gasket.

2.3 Design concept

14

3500XD Installation, Operation and Maintenance Instructions

Содержание Goulds Pumps 3500XD

Страница 1: ...Installation Operation and Maintenance Instructions 3500XD ...

Страница 2: ......