45

ALPHA

Stop wedges (if fitted)

A stop wedge can be fitted at the right hand-side of the

sprayer. The wedge is recommended to be used when

parking the sprayer at inclining grounds.

The wedges are removed from the brackets by pulling

the handle upwards and lift up the wedges.

Warning signal triangle

A reflecting warning triangle is placed in the cab behind

the driver’s seat.

In case of breakdown of the machine on public roads,

the triangle should be unfolded and placed 100 - 250 m

behind the machine to warn, if it is parked inconven-

iently or dangerously to the traffic.

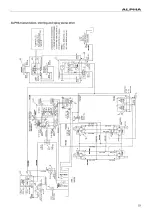

Starting aid by jumper cables

Be careful when using jumper cables to start vehicle

with flat battery.

The risks are the same as described in section “Charge

of battery” - see this section.

WARNING:

Use goggles and gloves when

working with batteries!

To avoid explosions it is important to connect jumper

cables in the following order:

1. Connect first ca-

ble (red) to posi-

tive terminal at

charged battery -

then to positive

terminal at dis-

charged battery.

2. Connect second

cable (black) to negative terminal at charged battery

first.

3. Then connect second cable to FRAME (not negative

terminal at battery!) at vehicle with discharged bat-

tery.

This to avoid sparks near the battery when connecting

the last cable to terminal.

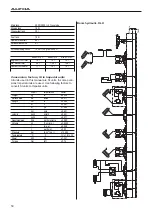

Trouble shooting

Operational problems, spraying equipment

In case of breakdowns, the same factors always seem

to come into play:

• Minor leaks on the suction side of the pump will re-

duce the pump capacity or stop the suction com-

pletely.

• A clogged suction filter will hinder or prevent suction

so that the pump does not operate satisfactorily.

• Clogged up pressure filters will result in increasing

pressure at the pressure gauge but lower pressure at

the nozzles.

• Foreign bodies stuck in the pump valves with the re-

sult that these cannot close tightly against the valve

seat. This reduces pump efficiency.

• Poorly reassembled pumps, especially diaphragm

covers, will allow the pump to suck air which will re-

duce capacity.

• Hydraulic components that are contaminated with dirt

will lead to rapid wear to the hydraulic system.

Therefore ALWAYS check:

1. Suction, pressure and nozzle filters are clean.

2. Hoses for leaks and cracks, paying particular atten-

tion to suction hoses.

3. Gaskets and O-rings are present and in good condi-

tion.

4. Pressure gauge is in good working order. Correct

dosage depends on it.

5. Operating unit functions properly. Use clean water to

check.

6. Hydraulic components are maintained clean.

Содержание ALPHA 2000

Страница 5: ......

Страница 6: ......

Страница 7: ......

Страница 9: ......

Страница 16: ......

Страница 24: ......

Страница 25: ......

Страница 26: ......

Страница 27: ......

Страница 28: ......

Страница 30: ......

Страница 31: ......

Страница 32: ......

Страница 33: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......

Страница 41: ......

Страница 42: ......

Страница 51: ......

Страница 52: ...52 ALPHA Notes...