18

ALPHA

NOTE!

On models with HARDI PILOT the EC operating

unit is controlled via the HARDI PILOT - See separate

instruction book.

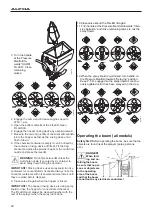

1. Choose the right nozzle size by turning the nozzle

bodies to a suitable nozzle for the spray purpose.

Make sure that all nozzles are the same type and size.

2. Open or close pressure agitation. (Remember pres-

sure agitation takes 5% to 10% of pump output).

3. Open main on/off valve

2

by pushing switch towards

green - spraying position

A

.

4. Open all distribution valves

4

by pushing switches

V

to position Green. A green indicator appears under

the EC-motor when valve is in spray position.

5. Open pressure adjustment valve by activating switch

C

until green finger screw

3

stops rotating.

6. Put the machine in neutral and set the engine revolu-

tions and thereby the number of revolutions of the

pump corresponding to the intended travelling speed.

Adjust the pressure adjustment valve

3

so that the

pressure gauge indicates the recommended pressure.

ADJUST THE PRESSURE EQUALIZATION SECTIONS

AS FOLLOWS:

8. Note the pressure and place the first of the distribution

valves

4

to position “off” (opposite “Green” position).

9. Turn the corresponding adjusting screw

1

until the

pressure gauge again shows the same pressure (turn

the screw clockwise for higher pressure, anticlock-

wise for lower pressure).

10.Place the next distribution valve to position “off”, and

adjust this one in the same way - one by one.

NOTE!

HEREAFTER ADJUSTMENT OF PRESSURE

EQUALIZATION WILL ONLY BE NEEDED IF YOU

CHANGE TO NOZZLES WITH OTHER CAPACITIES.

OPERATING THE CONTROL UNIT WHILE DRIVING:

11.To close the entire boom, operate switch

A

. This

takes the pressure from the pump. The liquid will then

return to the tank via the return system and serve as

agitation. The diaphragm anti-drip valves ensure in-

stantaneous closing of all nozzles. In order to close

part of the boom, activate one of the distribution

valves by the switch

V

of the section or sections to be

closed. The pressure equalisation device ensures

that the pressure does not rise in the sections which

remain open.

Remote pressure gauge (if fitted)

The remote pressure gauge measures the working

pressure in the boom tubes as close to the nozzles as

possible. This pressure reading will always be slightly

lower than the reading at the operating unit pressure

gauge.

The outputs stated in the nozzle charts are always

based on the pressure measured at the nozzle.

Always adjust pressure when calibrating and spraying

according to readings at the remote pressure gauge.

Filling of chemicals.

Chemicals can be filled in the tank in 2 ways:

1. Through tank lid.

2. By means of HARDI FILLER chemical filling device.

Filling through tank lid

The chemicals are filled through the tank lid - Note in-

structions on the chemical container!

WARNING!

Be careful not to slip or splash

chemicals when carrying chemicals up to the

tank lid!

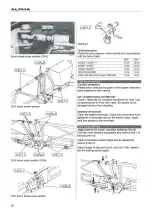

1. Make sure the EC on/off valve is switched off.

2. Set the MANIFOLD valves to correct position. Black

valve “Suction from main tank”, green valve towards

“Agitation” and Blue valve towards “Agitation”.

Adjustment of operating unit

T020-0007

3. Engage the pump and set engine revs. to 2200 r.p.m.

4. Add the chemicals through the main tank hole.

5. When the spray liquid is well mixed, turn handle on

the Pressure Manifold towards “Spraying” position.

Содержание ALPHA 2000

Страница 5: ......

Страница 6: ......

Страница 7: ......

Страница 9: ......

Страница 16: ......

Страница 24: ......

Страница 25: ......

Страница 26: ......

Страница 27: ......

Страница 28: ......

Страница 30: ......

Страница 31: ......

Страница 32: ......

Страница 33: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......

Страница 41: ......

Страница 42: ......

Страница 51: ......

Страница 52: ...52 ALPHA Notes...