44

ALPHA

14.Chock up the wheels to prevent moisture damage

and deformation of the tyres. Tyre blacking can be

applied to the tyre walls to preserve the rubber.

15.Engine preservation is carried out as descried in the

engine manual.

16.To protect against dust the sprayer can be covered

by a tarpaulin. Ensure ventilation to prevent conden-

sation.

Preparation after off-season storage

After a storage period the sprayer should be prepared

for the next season the following way:

1. Remove the cover.

2. Remove the support from the wheel axle and adjust

the tyre pressure.

3. Wipe off the grease from hydraulic ram piston rods.

4. Fit the pressure gauges again. Seal with Teflon tape.

5. Prepare engine according to instructions in the en-

gine manual.

6. Check all hydraulic and electric functions.

7. Empty the tank for remaining anti-freeze.

8. Rinse the entire liquid circuit on the sprayer with

clean water.

9. Fill with clean water and check all functions.

Emergency operation of the sprayer

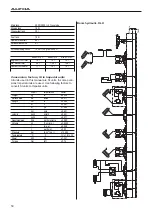

The boom

In case of power failure the boom can be operated

manually by pressing the individual buttons on the sole-

noid valves.

Remove the protection box of the solenoid valves at the

boom. Lock the by-pass valve. The boom can now be

operated by pressing the individual buttons on the sole-

noid valves.

The problem may be due to a blown fuse.

EC operating unit

In case of power failure it is possible to operate all func-

tions of the operating unit manually. First remove the

fuse in the junction box. Now manually turn the emer-

gency control knobs.

Towing

In emergency situations the machine can be towed a

short distance. In case of a engine break-down on pub-

lic road, and the machine must be pulled up on a truck.

IMPORTANT!

Never attempt any towing unless

the parking brakes in all 4 wheel motors are re-

lieved mechanically and the high pressure relief

valves on the hydrostatic pump are relieved! Failure to

do so will damage the transmission.

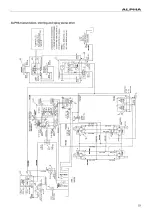

Hydrostatic pump

1. Remove the dust plug

2. Loosen the counternuts

A

3. Loosen the high pressure valves

B

a few turns CCW

with an Allen key

The machine can now be towed.

IMPORTANT!

Towing must only take place in emer-

gency situations. Max. towing distance is

15-20 m

. Max.

towing speed is

5 km/h

. Exceeding these limits can

damage the transmission.

When the towing is finished the transmission must be

set back to normal again.

1. Loosen the nuts and remove the brake relief yokes,

screws and nuts from the wheel motors

2. Fit the dust plug to the wheel motors again

3. Fit two 600 bar pressure gauges to the main pres-

sure measure outlets

4. Activate the parking brake

5. Start the engine set at 2000 r.p.m. and push the pilot

lever forward

6. Adjust the high pressure relief valve to 420 bar

7. Set the pilot lever in reverse and adjust the second

relief valve to 420 bar

8. Set the pilot lever back to neutral again

9. Release the parking brake and test the transmission

function

Hydraulic wheel motors

1. Remove the protection rubber dust plug

2. Fit the screw

3. Fit the yoke

4. Tighten the nut a few turns in order to relieve the

spring pressure. Do this on all 4 motors.

A

B

A

B

T060-0017

T060-0018

Содержание ALPHA 2000

Страница 5: ......

Страница 6: ......

Страница 7: ......

Страница 9: ......

Страница 16: ......

Страница 24: ......

Страница 25: ......

Страница 26: ......

Страница 27: ......

Страница 28: ......

Страница 30: ......

Страница 31: ......

Страница 32: ......

Страница 33: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......

Страница 41: ......

Страница 42: ......

Страница 51: ......

Страница 52: ...52 ALPHA Notes...