❏ ❏

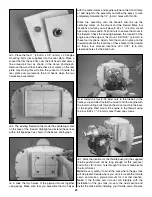

5. Locate the four 3/32"(2.4 mm) x 1"(25 mm) x 2"(51 mm)

plywood doublers

for mounting the wheel pants and the four

3/32"(2.4 mm) x 1"(25 mm) x 1"(25 mm)

plywood wheel pant

bearing blocks.

Make two sets as shown in the above

photograph by gluing them together using 6-minute epoxy.

Position the large doubler centered over the hole you drilled

previously in the wheel pant. When satisfied with the

location, mark its position and rough up the fiberglass with

80 grit sand paper. Then glue it into place using 30-minute

epoxy. When the epoxy has cured, drill another 5/32"(4 mm)

hole through the plywood doubler using the hole in the

wheel pant as a guide.

❏ ❏

6. Use a rotary tool or a drill to carefully create a

7/16"(11.1mm) clearance hole in the fiberglass wheel pant

and plywood doubler as shown in the above photo for the

axle unit base to fit into. Do not make this hole deeper than

9/64" (3.6 mm).

❏ ❏

7. Mark the location of the center of the plywood wheel

pant bearing block you prepared earlier as shown in the

photograph and drill a 5/32" (4mm) hole at this location.

Slip the 5/32" x 2"

axle

through the wheel pant and place

the bearing block over the axle shaft. Hold the block in place

against the outboard side of the wheel pant so that the

wheel pant is level and straight. Mark the location of the

block on the inside of the wheel pant. Rough up the

fiberglass with 80-grit sandpaper and glue the block into

place with epoxy.

DO NOT DRILL THROUGH THE WHEEL

PANT AT THIS LOCATION

.

❏ ❏

8. Install the axles onto the landing gear, making sure

the

stop nuts

are securely tightened.

❏ ❏

9. Temporarily place the wheels into the wheel pants

and slip them onto the axle shaft. As shown in the above

photograph, set the model on a flat surface and position the

aft end of the wheel pants 1" (25mm) above the surface.

Mark the locations, on the wheel pant, of the two holes

drilled in the landing gear while the aft end of the pants are

still elevated 1" (25mm) off your flat surface.

Remove the wheel pant from the landing gear and drill 1/8"

(3mm) holes at the marked locations. Epoxy two 4-40 blind

nuts into these holes inside the wheel pant but be careful

not to get the glue into the threads.

21