❏

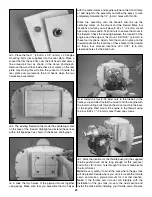

2. After the epoxy has cured cut a piece of a file folder,

index card, or any similar material and securely tape it to the

side of the fuselage so that it covers one of the mounting

blocks. Find the center of the mounting block and place a

mark on the card taped to the fuselage.

❏

3. Place the

cowl

on the fuselage in the correct

alignment and allow the engine drive washer to extend past

the front of the cowl at least 1/8" (3mm). When satisfied with

the alignment, tape the cowl in place and drill a 1/16"(1.6

mm) pilot hole through the cowl and the mounting block at

the location you marked on the card stock taped to the

fuselage. Enlarge the 1/16"(1.6 mm) hole in the cowl for

clearance with a 3/32"(2.4mm) drill bit to allow the #2 x 1/2"

(13mm) Phillips head screws to pass through the cowl.

Do not redrill the pilot hole in the cowl mounting blocks.

❏

4. Repeat this process at the locations of the other five

cowl mounting blocks. Mount the cowl using six #2 x 1/2"(13

mm) Phillips head screws and six #2 flat washers.

❏

5. You will need to cut other access holes in the cowling

for things like the fueling valve, needle valve, and glow

driver access to start the engine. Use this same method to

locate these holes. When finished you will have accurate

locations for these functions.

❏

1. The

aluminum spinner

supplied with this model is a new

and innovative design, which is universal and eliminates the

need for adapter nuts. To assemble the spinner, hold the

backplate and propeller (not supplied) together as one unit and

place onto the drive shaft.

Assemble and Install the Spinner

27