❏

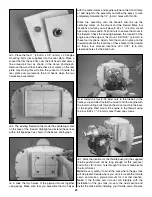

7. Attach a 12" servo extension to the throttle servo and

use tape or heat shrink material to secure it in place. Insert

the servo lead into the hole in the former located inside the

engine-mounting box. Place the servo, noting its orientation

in the photograph above, in the pre-cut space on the bottom

of the engine mount box as shown in the photo. Using the

same techniques shown on page 8, mount the servo by

drilling four 1/16"(3mm) holes using the hardware that came

with the servo to secure it into place.

Make the throttle pushrod from the supplied 2-56 x 17-1/2"

(466 mm) threaded one end throttle pushrod. Thread a nylon

clevis onto the threaded rod approximately 25 turns, add a

clevis retainer, and attach the clevis to the throttle arm on the

carburetor on the engine. Make necessary bends in the rod to

allow it to clear the engine and muffler. Then connect it to the

throttle servo arm by making a 90-degree bend and using a

nylon Faslink connector to secure it into place.

NOTE: This model will accept a number of different

engines including gasoline-powered engines. We have

just gone through the process of mounting a typical two-

stroke engine in the previous steps. We will now go

through the process of mounting a gas engine, using the

US Engines 41cc 2.5 Gas Engine (USEG0041). Notice that

the drive washer of any engine should be placed 6-1/2"

(165 mm) forward of the firewall. The use of some engines

may require alterations of the engine mounting box.

❏

1. Since this engine mounts with bolts from the rear of a

traditional firewall, we will make a plywood mount to be

attached to the engine. After this mount is attached to the

engine it will then be mounted to the existing firewall. First

of all make two 4" [102mm] x 4" [102mm] x 1/4" [6 mm]

plywood mounting plates [not supplied]. Draw center marks

on one of these plates as shown above. This plate will be

used as the front half of your mount. Do not glue these

pieces together at this time.

❏

2. Place the front side of the front plate (the one with the

center marks) against the back of the engine and mark the

location of the mounting holes with the engine centered on

the mount. Also draw the outline around the back of the

engine as shown in the photograph.

Note

: Depending on

the muffler used you may need to relieve a portion of the

mount to accommodate your muffler. Drill 1/4" [6mm] holes

in these four locations through both plates.

24