❏

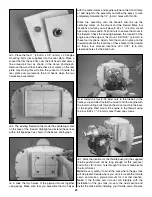

3. Place the four 1" (25 mm) x 1/4" (6 mm) x 20 engine

mounting bolts (not supplied) into the rear plate. Place a

socket that fits these bolts over the bolt heads and draw a

line around all four as shown in the above photograph.

Remove the wood from inside these four marks on the rear

plate only. Doing this will allow the socket to fit inside the

rear plate and countersink the bolt heads when the two

halves are assembled.

❏

4. The existing firewall on the model has centering marks

on the face of the firewall. Highlight and extend these lines

with a felt tipped pen as shown in the above photograph.

❏

5. Glue the two halves of the plywood mount together

using epoxy. Make sure that you assemble the two halves

with the center marks and engine outline on the front. Clamp

or add weight to the assembly and allow the epoxy to cure

completely. Saturate the 1/4" (6 mm) holes with thin CA.

Place the assembly onto the firewall and line up the

centering marks on the mount and the firewall. Mark four

locations at which you will place 8-32 x 1" (25 mm) socket

head cap screws and 8-32 blind nuts to secure the mount to

the firewall. Check the spacing between the location of the

engine and the edge of the mount. Drill 3/16" (4.8 mm) in

these four locations. Again, hold the mount in place on the

firewall and mark the locations of these holes on the firewall.

At these four marked locations drill 7/32" (5.6 mm)

clearance holes for the blind nuts.

❏

6. Install the four 8-32 blind nuts in the firewall in the

holes you just drilled. Install the mount onto the engine with

the four mounting bolts through the mount and into the back

of the engine. Next mount the engine to the firewall using

the four 8-32 x 1" (25 mm) socket head cap screws.

❏

7. Mark the location for the throttle push rod (the supplied

throttle pushrod will not be long enough for this purpose)

and drill a 1/8" (3 mm) hole through the mount, firewall and

the front former.

Note

: Be very careful to avoid the area where the gas tank

will be placed. Decide where you want to locate the throttle

servo and make a plywood mount for it at that location.

Note

: If the throttle servo mount will interfere with the

installation of the gas tank, move to the next section and

install the tank before installing your throttle servo. Be sure

25