When you are finished installing the flying wires on the left

side of the model, repeat the process to make the flying

wires on the right side.

❏

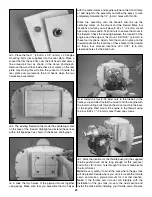

3. To make the flying wires for the tail surfaces start by

installing the 70-degree metal brackets. Note the locations

in the photograph above. Measure from the top of the fin to

a point 2" (51mm) down and 1/4" (6mm) forward from the

trailing edge of the fin and mark that location. Next,

measure from the outboard tip of each stab trailing edge to

a point 5" (127mm) inboard and 1/4" (6mm) forward from

the trailing edge of the horizontal stab and mark those

locations. In these three marked locations drill a 1/8" (3mm)

clearance hole through the fin and stabilizer. Saturate these

holes completely with thin CA.

At the bottom end of the fuselage, measure forward from the

tail post of the fuselage to a point 2-1/2" (64mm) and drill a

1/16" (1.6mm) hole at these locations on both sides of the

fuselage. Again, use the described procedure on page 8 to

install the brackets using two #4 x 1/2 " (13 mm) Phillips

head wood screws.

❏

4. Locate three 4-40 x 5/8" (15.9 mm) Phillips Head

Machine Screws, three 4-40 stop nuts, and eight 70-degree

metal brackets as shown in the photograph. Mount six

brackets at the three drilled locations; two brackets are

placed on top of the stab and two under it. The proper

installation is shown in the photographs.

Note

: The fit of the 4-40 x 5/8" (15.9 mm) Phillips Head

Machine Screws into the bracket is a bit tight but will fit; you

may need to thread it into place.

❏

5. Notice that the brackets are mounted on the fin as

shown with the indicated "bend" at the top as shown in the

photograph above.

❏

6. The brackets that are mounted on the stab have the

“bend” toward the outboard end of the stab as shown in the

photograph above.

31