❏

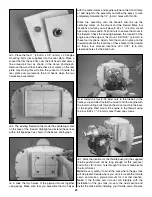

2. After removing the spreader bars from both

engine

mount

halves, fit the two halves together using the engine

to space the width properly. Notice that when you find the

proper width for your engine, the tick marks on the two

halves of the engine mount will no longer line up with each

other. Measure the distance between the two tick marks and

mark the center location between these tick marks. This

location will be used to properly align the engine mount with

the firewall markings.

Being careful not to move the width of the engine mount,

position the engine mount onto the firewall using the tick

marks and the marks you just made on all four sides of the

mount to align it with the horizontal and vertical lines on the

firewall. Mark the location of the holes with a

Dead Center

Hole Locator (GPMR8130)

.

❏

3. Drill four 7/32" (5.6mm) holes through the firewall at the

marks. Apply 30-minute epoxy to the four

8-32 blind nuts,

being careful not to get the glue into the threads and place

them into the holes on the back of the firewall. Attach the

engine mount to the firewall with four 8-32 x 1" (25mm)

socket head cap screws and #8 flat washers. This will draw

the blind nuts into the back of the firewall. Allow the epoxy

to cure.

❏

4. Position the

engine

on the mount so the engine drive

washer is 6-1/2" (165mm) from the firewall. This will provide

the correct clearance between the spinner and the cowl.

❏

5. Using your Dead Center Hole Locator again, mark the

hole locations on the engine mount. Drill #29 (or 9/64")

holes through the engine mount at the marks you made,

then tap 8-32 threads into the holes. Mount the engine to

the mount with four 8-32 x 3/4" Socket Head Cap Screws

and #8 washers.

❏

6. Test fit the

muffler

to be used on your engine. The

O.S.

1.60 FX (OSMG0661)

is shown in this manual. Bisson

Custom Mufflers produce a

Pitts Style Muffler (BISG4116)

that is designed specially to fit this engine and is shown in

the photo above.

23